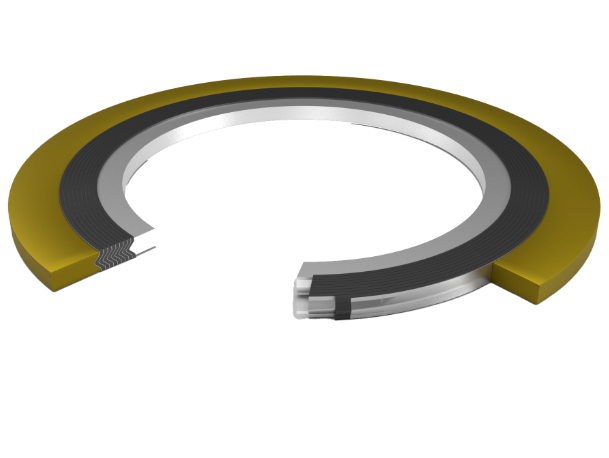

Back Up Rings

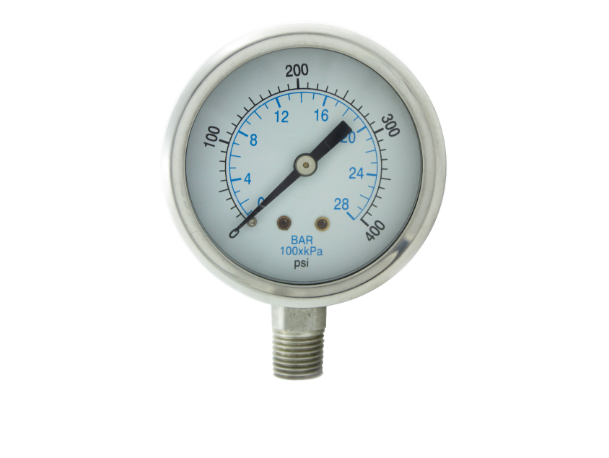

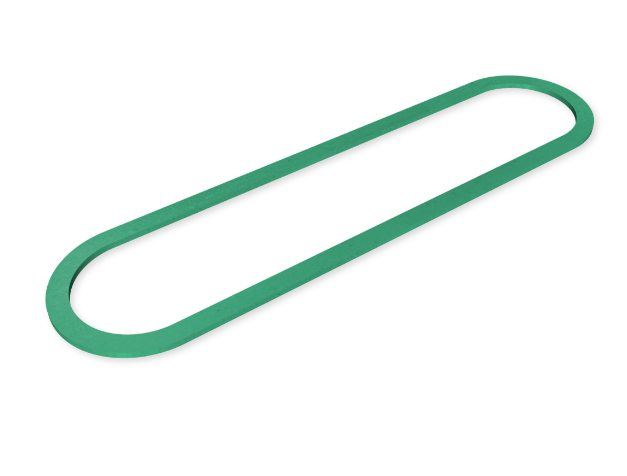

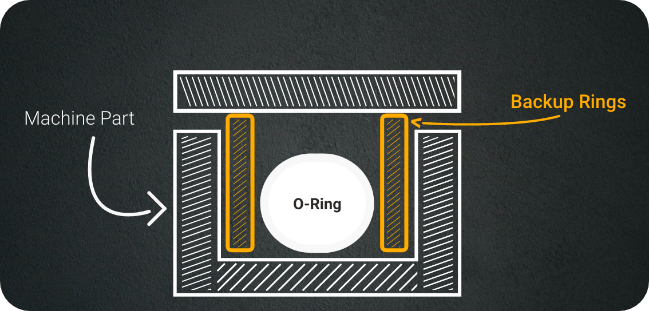

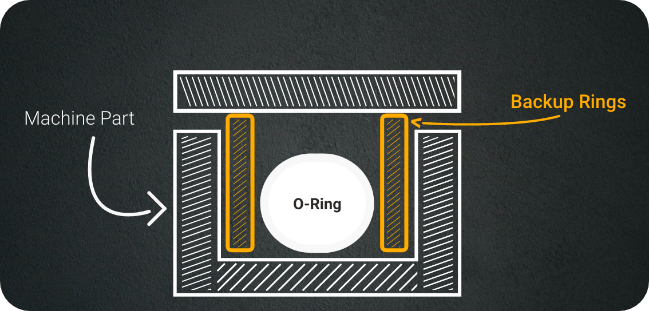

Backup rings are commonly installed with rubber o-rings to help improve their performance. These rings are designed to limit o-ring clearance gaps and are used in high-pressure sealing situations greater than 1500 PSI. Using these rings will prevent the o-ring from becoming damaged or extruded, causing failure of some systems. Generally, backup rings come in two different shapes, flat-sided and concave. The reason behind the introduction of the concave backup ring was to relieve the pressure off the o-ring as it deforms under pressure. However, there are no real performance benefits from either a flat-sided or concave backup ring.

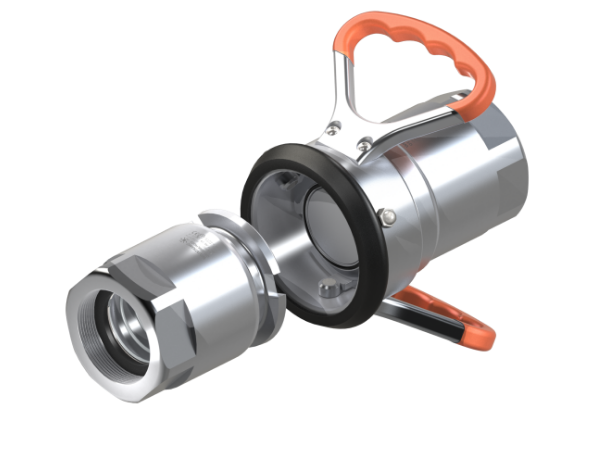

Backup rings are used in many different industries around the globe. A few typical applications include hydraulic systems, high-pressure hydraulic systems, and high-pressure valves. In most applications, it is often best to use two backup rings, one above and one below the o-ring. This application will provide the best support for the o-ring and allow for a smooth operation.

Types of Backup Rings

PTFE (Teflon) Spiral

Spiral backup rings are overlapping and coiled material. The overlapping coil provides extra support under higher pressures. While these types of backup rings are not heavily used in modern systems, it is used for very specific purposes.

PTFE (Teflon) Solid

Solid backup rings are easy to install and are super popular when working with rods and pistons. Face seals use these quite often because of the easy installation. These backup rings usually do have some stretch to them to slide into their place.

Ptfe (Teflon) Split

PTFE Split, scarf cut, backup rings are the most used backup rings today. They are easy to install, be made of harder materials, and handle extreme pressures. Because of the gap, it can easily be opened or closed to fit most extrusion gaps when needed. These backup rings are made with hard materials such as PTFE (Teflon) so it can withstand high pressure situations. However, the split in the ring can cause micro tears on the O-Ring causing premature failure.

PTFE (Teflon) Contoured

Contoured backup rings are used in both static and dynamic applications. These rings are useful when not tightly controlled. The contoured face of these rings allows a seamless fit with the diameter of the o-ring. Using two backup rings are always beneficial when you can

Related Items

Suggested Articles

Get To Know Materials: PTFE

What is PTFE? Polytetrafluoroethylene, better known as PTFE, is a material founded by E.I. DuPont in 1938 and has become a widely popular choice of material when sealing a wide range of chemicals, acids, bases, and steam. This tough material....

How Weather Impacts O-Rings

The impact of weather needs to be taken into consideration when choosing the type of material that best suits your application. It is easy to overlook how weather conditions will impact o-rings that are outdoors, but failing to consider weather exposure...

Stay Connected

Get the latest updates on products, new knowledge base posts, and everything APG!