Menu

Close Menu

Updated: October 2023

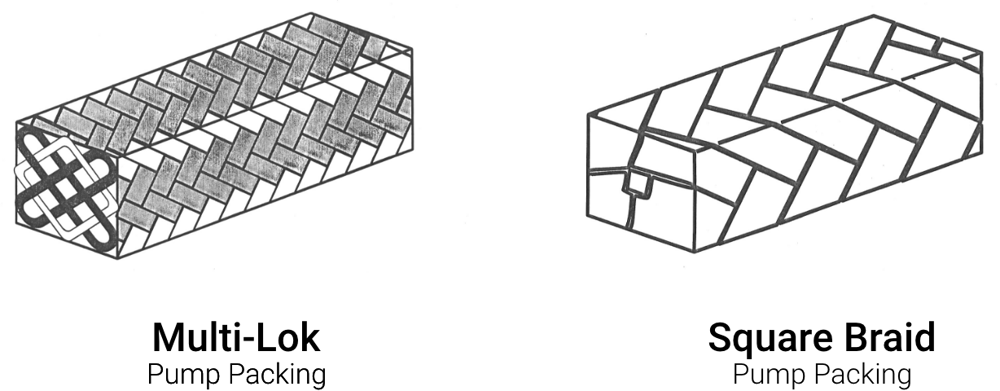

Pump packing is the earliest form of sealing pumps and is widely used over the mechanical sealing option. These packings are often braided, fibrous material, such as graphite or non-graphite acrylic, PTFE, or other such materials. These materials are stuffed into the pump’s seal chamber (stuffing box), between the rotating member and the body of the pump or valve. By tightening the gland against the outboard ring, the pressure is allocated to the packing set. This expands the rings which create a seal.

There are a few advantages in using pump packing such as the upfront cost, wide availability, simplicity to install, and most importantly, it’s easily replaceable with a minimal amount of downtime. This means you can easily replace any worn-out packing quickly to keep the pump running.

Just like with o-rings and gaskets, there are various types of materials, shapes, and sizes APG readily stocks square braided packing but will ship any material you would like. Below you’ll find a list of packing materials with their benefits and advantages. The information below was gathered uses many resources from SEPCO.

Flax (1460)

Used for packing brine, cold water, and cold oils. This yarn is mostly used in the shipping industry. Flax can withstand 1885 FPM, a pH of 5-9, and 220ºF (104ºC).

Acrylic (1173)

Used for packing mild acids, alkalies, brines, and oils. This yarn is used as a form of low-cost packing in many industries. Acrylic yarn can withstand 1885 FPM, a pH of 4-10, and a temperature up to 450ºF (232ºC).

Kynol (1177)

Used primarily in chemical, pulp, and paper industries. Kynol yarn can withstand 1800 FPM, a pH of 1-13, and temperatures up to 500ºF (260ºC)

Nomex

Used for caustics, mild acids, chemicals, air, oil, gases, and solvents. Nomex yarn is mostly used in the fire protection industry. This material can withstand 1800 FPM, a pH of 3-11, and temperatures up to 500ºF (260ºC).

Filament PTFE (1169)

Being PTFE, this yarn has a high resistance to many chemicals, acids, and corrosion. PTFE yarn does not have great thermal conductivity unless paired with graphite lubricants. This fiber can withstand 1200-4900 FPM depending on the use of graphite lubricants. PTFE can withstand a pH of 0-14 and temperatures up to 500ºF (260ºC).

Encapsulated PTFE (1180)

Used mostly in mixers, pumps, agitators, reactors, and blenders. Encapsulated PTFE yarns are expanded with graphite which creates a stronger microstructure. This yarn can withstand 3300-4400 FPM, depending on the lubricant, a pH of 0-14, and temperatures up to 550ºF (288ºC).

Carbon / Graphite (1176)

This type of yarn is manufactured through a heat treatment process until it achieves the desired carbon or graphite content. These materials can withstand 4000 FPM, have a pH of 0-14, and have 650ºF (343ºC).

Flexible Graphite (1171)

This yarn has excellent thermal properties and can be mixed with other fibers to form a mixed yarn. It alone can withstand shaft speeds of less than 4000 FPM, a pH of 0-14, and 850ºF (454ºC).

APG Wants To Be Your Packing Supplier

APG believes in providing the highest quality products, every-time. All our packing material is quality material used all over the world. Our knowledgeable sales team can get you started on which material is the best use for you and your machinery, If you do have any questions, please contact us or look at our Knowledge Base for up-to-date articles about all of our products and services.

Packing & Gasket Catalog

The Packing & Gasket Catalog shows custom fabrication, spiral wound gaskets, braided packing, and related products, packing & gasket tools, sheet materials & tapes, o-ring cord & stock...

Get the latest updates on products, new knowledge base posts, and everything APG!