Menu

Close Menu

PTFE envelope gaskets are used in a variety of industries, including plumbing and aerospace. These gaskets seal large openings between metal parts and pipes, providing an effective barrier against water or liquid contaminants in industrial applications. They're made from high-density polytetrafluoroethylene (PTFE) , which has a high melting point, low coefficient of friction and good chemical stability characteristics that make it ideal for use as a sealing medium between metal parts. The main benefit of using PTFE envelope gaskets is their ability to seal large areas while maintaining high bolt loading—which means they can be used with other metals without compromising performance or causing damage over time.

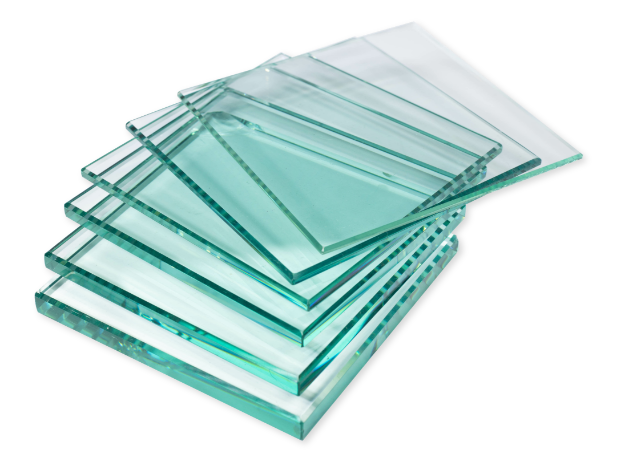

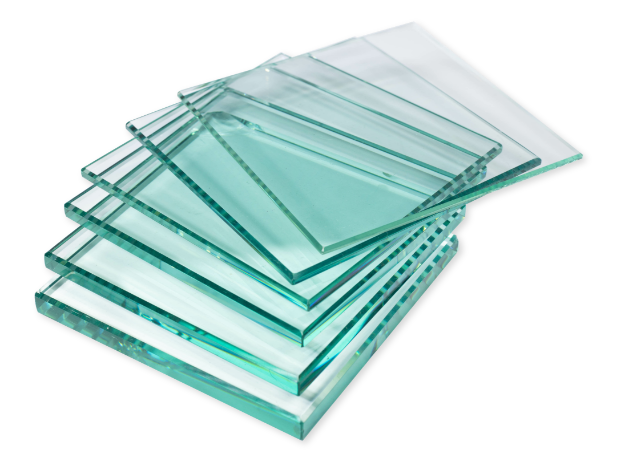

An envelope gasket is a PTFE gasket enclosed in a metal support. The metal support provides strength and stiffness to the gasket, allowing it to be used with glass-lined, cast iron, metal, or concrete flanges. Envelope gaskets are also called “encased” or “enclosed” PTFE seals because they create an airtight seal between the two mating surfaces of your equipment.

The metal core is the main component of the gasket, providing strength and stiffness. The metal core uses a unique shape to accomplish this feat, and it can be made from different materials.

The envelope gasket uses a metal core that's shaped like an envelope to provide support for its non-metallic parts. It’s important to note that the envelope gasket does not have any foam or silicon fillers; instead, it relies on its shape alone for rigidity and support.

What is a Gasket and How Does it Work? ->

Envelope gaskets can be used in a variety of applications, including high-pressure, high temperature and corrosive environments. They’re also effective at sealing small gaps between flanges and shafts as well as larger distances between multiple flanges or surfaces.

Envelope gaskets are often used in the oil and gas industry to seal connections between pressure vessels, piping systems and valves. In addition to their ability to withstand pressure and temperature extremes, envelope gaskets also have excellent resistance to chemicals that could compromise the integrity of other types of gaskets (such as neoprene).

PTFE envelope gaskets are ideal for use with glass-lined, cast iron, metal, or concrete flanges. This type of gasket can be used on a wide variety of flanges and is especially useful for non-standard flanges that require a high degree of sealing performance.

The best things about PTFE Envelope Gaskets are:

See the Top 6 Considerations in Picking a Gasket ->

PTFE envelope gaskets are a great way to seal your equipment. They’re strong enough to withstand high pressure and temperatures, yet flexible enough to accommodate expansion or contraction in the flange area. You can use them with glass-lined, cast iron or concrete flanges as well as polymeric pipes or fittings that might be prone to damage from high temperatures or pressures. If you need help finding the perfect product for your application, contact us today!

Stay Connected!

Get the latest updates on products, new knowledge base posts, and everything APG!

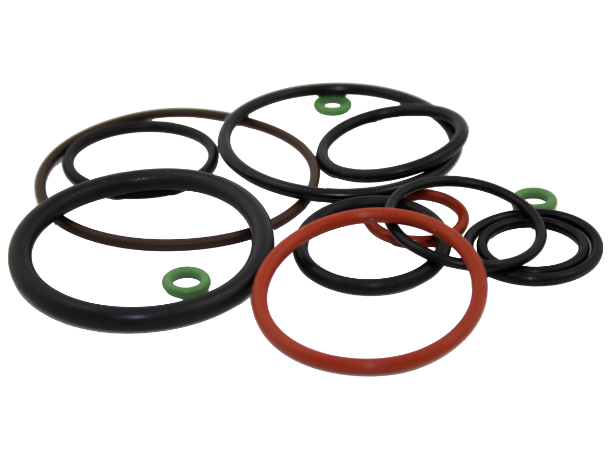

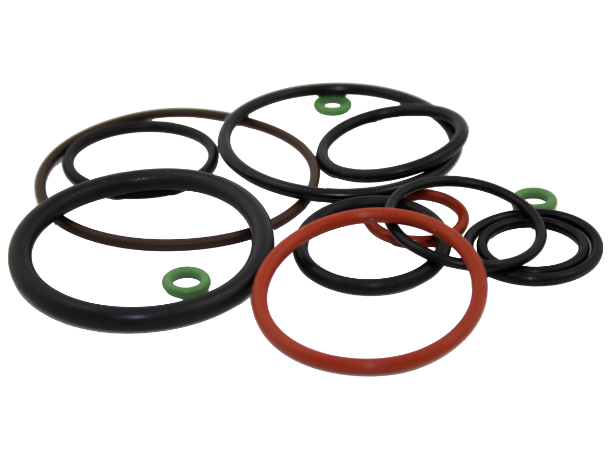

O-Ring Handbook: Your Guide to O-Rings

Read More...What to Look for in a Fluid Sealing and Conveyance

Read More...Get to Know Our O-Rings: Types and Applications

Read More...

About The Author

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

Leave a Reply

Your email address will not be published. Required fields are marked*