Menu

Close Menu

Compression pump packing can be made from various packing fibers. Depending on the type of material, they can prevent leaks and extend the life of pumps. Constructed of soft material, this product is stuffed inside the “stuffing box” of a pump which sits between the rotating member and the body of the pump or valve to form a seal.

There are 8 types of compression packing material. Each of these materials perform differently depending on temperature, shaft speeds, and medium they are sealing. The 8 types of packing are:

Flax compression packing uses the quality of flax fibers braided together to form this packing material. There are two different types of flax packing, tallow lubricated and PTFE (Teflon) impregnated. However, flax compression packing material is best used in brine, cold water, and cold oils.

Novoloid packing fibers are considered to be the most popular type compression packing. It offers great thermal conductivity and can withstand higher shaft speeds. Some novoloid packing may have special lubrication processes applied for a longer lasting packing life.

Novoloid contains no silicon, sulfur, or wax, and is an excellent alternative to graphite packing. In addition, it can be used in places that graphite packing cannot be used in such as the pulp and paper industry as well as chemical industries. Novoloid packing is great in steam, water, acid, chemical, and paper industries.

Aramid compression packing performs well in abrasive environments. Some packing materials are coated in PTFE and a light inert oil to improve resistance to mild acids, chemicals, air, oil, gases, and solvents. This material is also used as an anti-extrusion ring and placed at both ends of a packing set.

PTFE, or Teflon, compression packing have a higher resistance to chemicals and lower levels of friction compared to all other compression packings. However, if the PTFE packing material is not lubricated with graphite, it can have poor thermal conductivity.

Depending on the lubricant, PTFE can be softer and more flexible with improved peripheral speed characteristics. This material can be used on any equipment as long as braided packing is generally used on it.

This compression packing is constructed of an expanded PTFE which encapsulates graphite or a lubricant. The expansion process produces a microstructure that has a higher strength than PTFE filament fibers. These packing materials are lubricated with no sulfur, silicone, or wax products.

These packings are proven industry performers. They use a special heat treatment process to achieve the desired graphite or carbon content. These materials can be treated with PTFE to help prevent color combination and carbon migration.

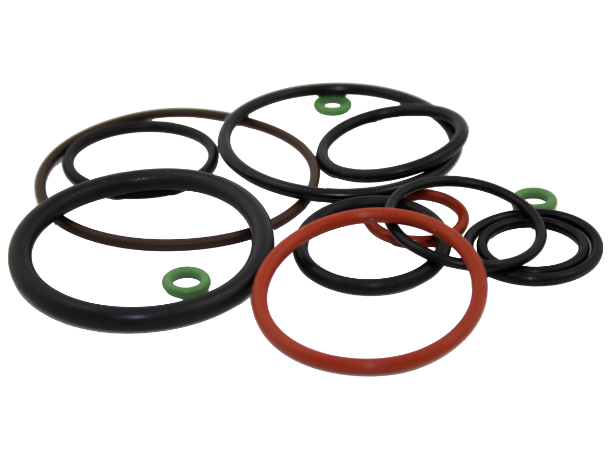

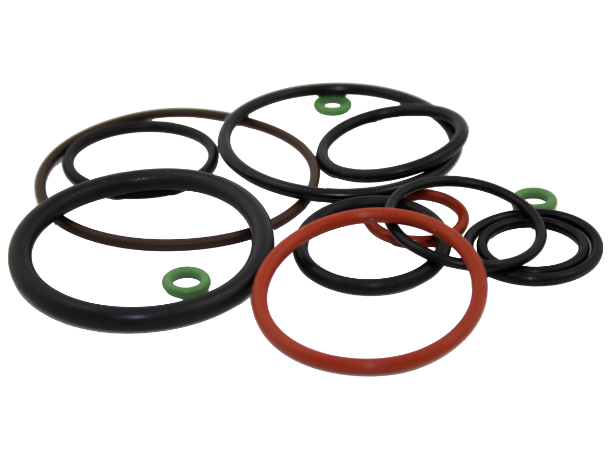

O-Ring Handbook: Your Guide to O-Rings

Read More...What to Look for in a Fluid Sealing and Conveyance

Read More...Get to Know Our O-Rings: Types and Applications

Read More...

About The Author

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

Leave a Reply

Your email address will not be published. Required fields are marked*