Menu

Close Menu

Pump packing is the earliest form of sealing pumps and is widely used over the mechanical sealing option. These packings are often braided, fibrous material, such as graphite or non-graphite acrylic, PTFE, or other such materials.

The packing material is stuffed into the pump’s seal chamber (stuffing box), between the rotating member and the body of the pump or valve. By tightening the gland against the outboard ring, the pressure is allocated to the packing set. This expands the rings which create a seal.

Just like with o-rings and gaskets, there are various types of materials, shapes, and sizes APG readily stocks square braided packing but will ship any material you would like.

Style: 1171

APG’s Style 1171 valve packing is a pure flexible graphite bonded to a fiberglass carrier for strength and thermal stability. This forms a dense and pliable braided valve packing and passes API Standard 600 fire test. Style 1171 is recommended for use in rotating shafts where high shaft speeds and thermal conductivity are required with operating temperatures up to 850°F / 454°C and unlimited shaft speeds in applications such as chemical processing, mining, oil and gas, pulp and paper, and nuclear among other others.

Learn More on Knowledge Base →

Style: 1173

APG’s Style 1173 pump packing is saturated and sealed after braiding with PTFE (Teflon) particles which provides a greater degree of chemical inertness, lower coefficient of friction, and prevents penetration of chemical fluids. To assure good break-in characteristics, a light oil is applied. Style 1173 is recommended for operating temperatures up to 500°F / 260°C and shaft speeds up to 1850 feet per minute in caustics, mild acids, difficult chemicals, oils, and general chemical plant applications in general service, rotating and reciprocating pumps and agitators.

Learn More on Knowledge Base →

Style: 1177

APG’s Style 1177 pump packing is braided Novoloid fibers with PTFE (Teflon) impregnation, lubricated in a proprietary, nonpetroleum lubricant containing no sulfur, silicon, or wax which transforms each individual fiber into a reservoir of lubrication for longer packing life. Because of its ability to conform to stuffing box configuration, it requires less gland load for an effective seal and is an excellent high-performance alternative. Style 1177 is recommended for operating temperatures up to 500°F / 260°C and shaft speeds up to 1800 feet per minute in steam, water, acid, chemical, and solvent applications for multi-use in chemical plants and pulp and paper mills.

Learn More on Knowledge Base →

Style: 1178

APG’s Style 1178 pump packing is constructed of non-asbestos aramid fibers which are a synthetic fiber displaying many characteristics of asbestos. Each stand is individually treated with a PTFE coating and a light, inert oil which fills and seals interstices in the packing fibers then is forced air-dried. This packing will not wick. Style 1178 is recommended for operating temperatures up to 500°F / 260°C and shaft speeds up to 1900 feet per minute in general service, caustics, mild acids, chemicals, air, oil, gases, solvents and general chemical plant applications for rotating and reciprocating shafts and all equipment on which braided asbestos packings are used. This product is a great performer in extreme abrasive environments.

Learn More on Knowledge Base →

Insert Code

Style: 1180

APG’s Style 1180 pump packing has 100% GFO® fibers with the W. L. Gore seal of approval with finely ground particles of the highest quality graphite encapsulated in the PTFE matrix to eliminate graphite migration and lubricated with a proprietary high-speed lubricant. Style 1180 is recommended for operating temperatures up to 550°F / 288°C and shaft speeds up to 4400 feet per minute in all corrosive applications suitable for PTFE & graphite for use in all reciprocating and rotating shafts.

Learn More on Knowledge Base →

Style: 1182

APG’s Style 1182 valve packing is a braided carbon yarn with Inconel wire inserted over a pliable homogeneous core of material. The braid is made from a high temperature, Inconel wire-inserted high temperature carbon yarn jacket over plastic core. The finished packing is treated with a high temperature graphite lubricant and a corrosion inhibitor. Style 1182 is recommended for use in steam, air petroleum products, and hot gasses up to pressures of 2500 psi and operating temperatures up to 1200°F / 649°C.

Learn More on Knowledge Base →

Style: 1189

APG’s Style 1189 pump packing has non-asbestos fibers treated with a specially formulated blend of lubricants having a saxoline base. Each strand is individually coated with graphite and the braid surface receives a final secondary surface coating of graphite. The ductile nature of the lubricant prevents wicking and provides superior sealability. Style 1189 is a good general service packing recommended for operating temperatures up to 450°F / 232°C and shaft speeds up to 1885 feet per minute for use in mild acids, alkalis, steam, brine, and oil.

Learn More on Knowledge Base →

Style: 1169

APG’s Style 1169 pump packing has pre-lubricated yarns to provide a softer, more flexible packing with improved peripheral speed characteristics and exothermic properties. This ensures a virtually indestructible packing with no glazing at higher speed applications, an inert, lower coefficient of friction, improved thermal resistance, and high compressive strength. Style 1169 is recommended for operating temperatures up to 500°F / 260°C and shaft speeds up to 1200 feet per minute for use in the most severe services in all oxidizers and corrosives with one exception: molten alkali metals.

Learn More on Knowledge Base →

Style: 1170

APG’s Style 1170 pump packing is manufactured from the purest dry PTFE fibers and is lubricated with a proprietary food-grade lubricant for faster break-in and reduced shaft wear. This lubricant complies with the FDA and USDA requirements under Title 21 Food and Drugs, 178.2570, Lubricants with Incidental Food Contact, 177.1550, Perfluorocarbon Resins and contains only materials permitted for food contact use by the U.S. Department of Agriculture and the Food and Drug Administration. Style 1170 is recommended for operating temperatures up to 500°F / 260°C and shaft speeds up to 1200 feet per minutes for use in anywhere FDA material is required, all applications in the food processing industry, or any equipment where braided packings are commonly used.

Learn More on Knowledge Base →

Style: 1174

APG’s Style 1174 valve packing has PTFE fibers treated with a PTFE dispersion which fills and seals all voids in the packing body. After braiding, a PTFE coating is applied and the packing is forced air dried. This packing will not wick making it an excellent choice for valves, hatch seals, and inspection port seals. The PTFE construction makes it impervious to almost all chemicals and acids and is an excellent valve stem packing for all chemicals and corrosives; inert to all fluids except for molten alkali metals. Style 1174 is recommended for operating temperatures up to 500°F / 260°C for all severe chemical and corrosive services where an inert packing material is essential.

Learn More on Knowledge Base →

Style: 1175

APG’s Style 1175 pump packing features braided graphite fibers with a minimum of 99% carbon and 1% ash. A surface lubricant is applied to prevent wicking and to provide a bearing film between the shaft and the packing material. This dispersion coating of graphite does not contain any hydrocarbon, PTFE, or any silicone additive and the final packing can be nuclear certified. Style 1175 is recommended for operating temperatures of up to 6000°F / 3316°C and unlimited shaft speeds for use in valves, agitator shafts, reciprocating rods, and plunger rods where minimum leakage is required under severe service conditions where strong acids and caustics are present.

Learn More on Knowledge Base →

Style: 1176

APG’s Style 1176 pump packing contains a unique combination of amorphous carbon fibers (PAN fibers) treated throughout with fine particles of graphite. It is an excellent alternative in applications where asbestos packings are not permitted and graphite yarn packings are too expensive. Style 1176 is recommended for operating temperatures up to 850°F / 454°C and shaft speeds up to 4000 feet per minute for general service on rotary and reciprocating shaft and as end rings on high-temperature valves in chemical services in which carbon is suitable.

Learn More on Knowledge Base →

Style: 1179

APG’s Style 1179 pump packing features carbon filament fibers made from a PAN base, with a minimum carbon content of 95%. Staple fibers from PAN produce a more flexible packing than filament fibers, which tends to fracture when bent. Each individual strand is coated with pure PTFE and cured before braiding which prevents color contamination and carbon migration. During the braiding process, pure PTFE is applied throughout the body of the packing. The packing is lubricated under hydraulic pressure with a proprietary nonpetroleum lubricant, containing no sulfur, silicone, or waxes. Style 1179 is recommended for operating temperatures up to 600°F / 345°C and shaft speeds up to 3000 feet per minute for most chemical services, except strong oxidizers, in pulp mill equipment, steaming vessels, top separators, refiners, outlet devices, blow pumps, stock pumps, agitators and valves.

Learn More on Knowledge Base →

Style: 1460

APG’s Style 1460 flax pump packing is constructed with a square braid and lubricated with a pure edible tallow and wax compound, which is non-graphitic. This packing is non-contaminating and does not contain graphite. Useful for sealing furnace and gas generated doors, high-pressure rams, and accumulators, Style 1460 is recommended for operating temperatures up to 220°F / 104°C and shaft speeds up to 1885 feet per minute for all chemicals and corrosives, including brine, cold water, and cold oil in reciprocating and rotary shafts, plungers, hydraulic rams, and stern tubes.

Learn More on Knowledge Base →

Style: 1463

APG’s Style 1463 flax packing is constructed with a square braid, impregnated throughout with an ungraphited, pure PTFE dispersion, which acts as a surface leveler and fills in voids in the packing, a saturant to prevent wicking, a lubricant to reduce friction and heat, and a protective shield around the flax fibers, preventing fluid penetration and fiber break down. These characteristics make it an excellent paper stock packing. Style 1463 is recommended for operating temperatures up to 220°F / 104°C and shaft speeds up to 1885 feet per minute in reciprocating and rotating shafts for paper mill applications such as claflins, hydrofiners, and stock pumps or wherever product discoloration must be prevented, such as in the food and bleached paper industries.

Learn More on Knowledge Base →

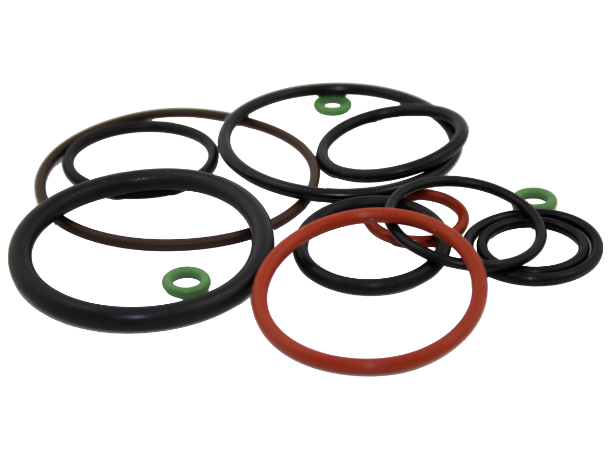

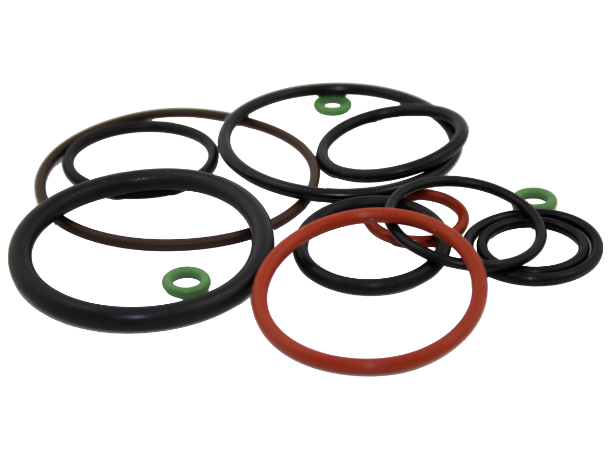

O-Ring Handbook: Your Guide to O-Rings

Read More...What to Look for in a Fluid Sealing and Conveyance

Read More...Get to Know Our O-Rings: Types and Applications

Read More...

About The Author

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

Leave a Reply

Your email address will not be published. Required fields are marked*