Menu

Close Menu

APG and Flange Guards have teamed up to bring the best-selling safety spray shield from across the pond here to the United States. This safer, quicker, and better solution to quickly sealing leaks around flanges makes operators more inclined to re-fit after removal. Our PDT technology makes Sureband® the most COST EFFECTIVE shield design on the market!

SUREBAND PDT (Pressure Diffusion Technology) uses a specially formulated multi-layered mesh that is held against the flange. The pressure is diffused in a controlled manner thus preventing formation of a mist/vapor cloud. At the point of exit from the shield, the leak takes the form of a safe, vertical drip or stream.

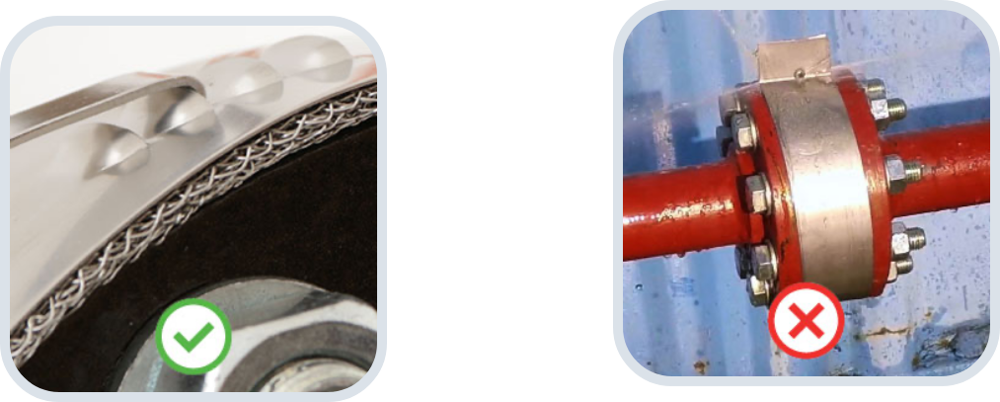

Our leak testing facility has proven that pressure diffusion is required to prevent spray and mist formation. However, many shield designs have no diffusion – and this can actually create a worse leak than no shield at all.

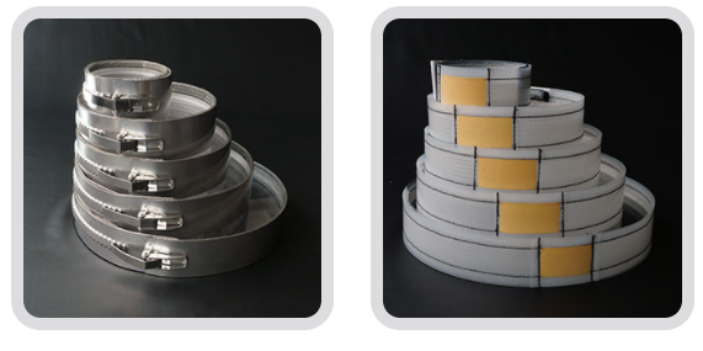

Our Sureband® Clear Shields are manufactured from All-PTFE materials (no fiberglass) comprising clear ECTFE outer and multi-layered PTFE mesh inner. This material provides unparalleled chemical resistance.

PDT Pressure Diffusion Technology

Multi-layered PTFE mesh specially formulated to diffuse pressure release, preventing spray and mist formation. The liquid simply drops vertically, removing all hazards

Quick-Connection

Industrialized & strengthened Velcro provides a simple but highly effective means of fitting & removal

Litmus Indicator Patch

Immediate visual leak indication for acids & alkali applications. Easily replaced, so the shield doesn’t have to be.

Multi-Sizes

This shield is cleverly designed to fit multiple flange sizes. This means less stockholding and more flexibility.

All PTFE

The shield body contains no fiberglass. This means it will not degrade in highly aggressive chemical environments.

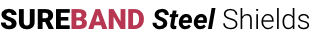

Our Sureband® Steel Shields shield uses only the highest quality materials. This simple design outlasts all other shield types/materials in our in-house pressure testing.

Most important is the internal multi-layered steel mesh, which effectively diffuses pressure releases – thus preventing spray and mist formation.

More than any other shield in our range, beware of cheap copies without adequate mesh or any form of testing. Our 316 st/st guard is well suited to Steam, Fuel oil, Lube oil, Diesel. All our designs are tested on our hydrostatic pressure test facility, test certificates are available on request.

1. Multi-Layered Steel Mesh

Critical for safety, to avoid spray and unwanted mist formation (which is a consequence of ill-fitting shields with no mesh). The mesh effectively diffuses a pressure release, creating a safe vertical drip.

2. Quick-Connection Latch

Provides quick and easy fitting & removal without any special tools. This is very useful for harsh environments where gloves, chem-suits, and other conditions make installation difficult

3. All 316 Stainless Stell As Standard

No weak points, 3.1b material certificates available on request.

We also manufacture a range of flexible thermal insulation covers.

OUR QUICK-FIT CONNECTION HAS TWO IMPORTANT BENEFITS

Installation time can often cost more than the shields themselves. SUREBAND is fitted within seconds (rather than minutes). This saves time and money, whilst maintaining maximum safety.

Ongoing pipe maintenance requires shields to be removed. Gloves are generally mandatory, so pull-cord knots are typically to cut off rendering conventional shields useless. With SUREBAND, operatives are much more likely to re-fit shields (shields are often used within hazardous area zoning calculations, thus failure to re-install the shields invalidates zone classification)

MULTI-SIZE FUNCTION increases flexibility & reduces stock holding

Our clever Multi-Size system means one shield fits multiple flange sizes. Only 5 shield sizes are needed to fit all 28 standard flanges between ½" and 6" pipe sizes (across multiple pressure classes).

This reduces stockholding & speeds up delivery dramatically. It also prevents fitting errors where site surveys are required (fixed size shields require precise flange measurement).

BEST-IN-CLASS MATERIALS Using the highest quality materials, resulting in the longest service life

100% ETFE and ECTFE. Conventional fabric shields are made from fiberglass coated with PTFE. Over time, with exposure to corrosive environments, the fiberglass is exposed and ultimately degrades. SUREBAND Clear contains no fiberglass, ensuring a considerably longer life span.

100% ETFE and ECTFE. Conventional fabric shields are made from fiberglass coated with PTFE. Over time, with exposure to corrosive environments, the fiberglass is exposed and ultimately degrades. SUREBAND Clear contains no fiberglass, ensuring a considerably longer life span.

Comprising all-316 stainless steel outer band and inner, multi-layered mesh. SUREBAND Steelworks effectively at high pressure and wide temperature ranges. The quick-connection latch makes installation simple.

If you have questions please don’t hesitate to contact us or look into our knowledge base to help find the right answer. We look forward to exceeding your expectations in both quality and service.

Getting To Know: Sureband® Clear

Flange spray shields are used in a variety of industries where their primary application is the prevention of mist formation and dangerous/harmful spray-outs resulting from failing pipe...

Getting To Know: Sureband® Steel

This shield design comprises a steel band and an internal layer of steel mesh which is compressed against the flange itself. This mesh, which is crimped along the center to fill...

Written By:

Please Fill Out This Form To Be Contacted By An Expert