-

-

September

2021

Understanding the In's and Out's About the O-Ring Vulcanization Process

- o-ring

- vulcanizing

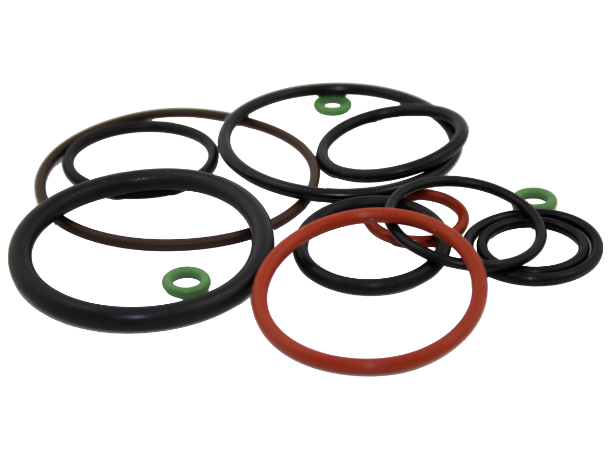

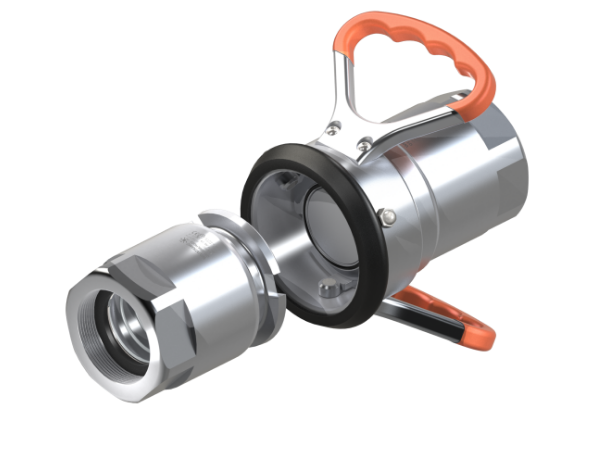

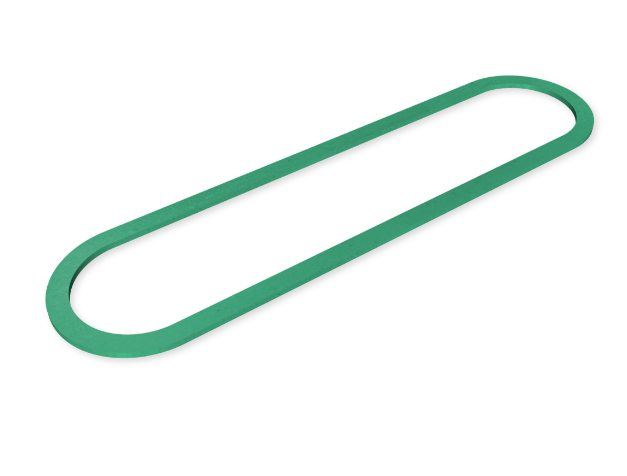

Here at APG, we have a dedicated team with decades of O-ring knowledge and experience readily available to vulcanize any custom O-Ring when you need it most. The vulcanization process consists of using cord material, adhesive, heat, and pressure to combine the two ends together to create a custom O-Ring in a matter of minutes. To get a glimpse of our process, watch our short video.

Cord Selection

The vulcanizing process begins with picking the right O-Ring cord, as each elastomer has different chemical properties and reacts differently to various environments and temperatures. Failure to pick the right material could cause your equipment to fail, or be unsatisfactory. Below is a list of the most popular cords APG has available for vulcanization and for individual sale. To inquire about these materials or any others, please reach out to our team using the form below.

Popular Materials APG Has Readily Available In Stock

|

Aflas Aflas® is unique compared to other rubber materials as it has a wide range of resistive properties such as, high temperatures, chemicals, electrical, petroleum, steam, weathering, and ozone. |

|

|

Fluoroelastomer Fluoroelastomer performs well in many different environments such as a variety of oil and petroleum products, high vacuum situations, ozone, weather, high temperatures, and strong acids. This material is commonly used to seal leaks, valves, or pumps. |

|

|

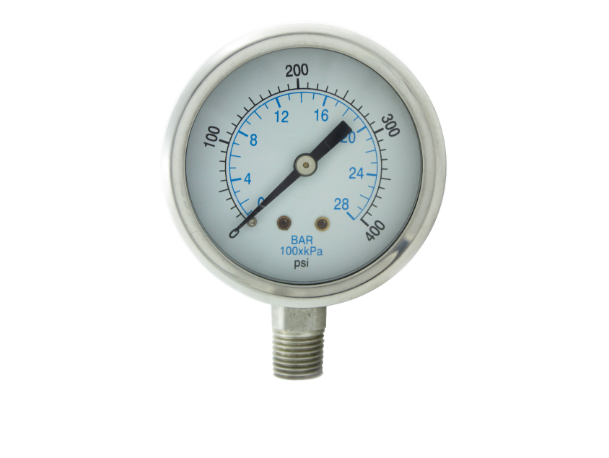

FKM (Viton) FMK (Viton) has a super high heat resistance just like fluoroelastomers. The temperature range goes from -15ºF to 400ºF with exposure to higher temperatures possible for a short period. This makes them a great choice when handling high-temperature and explosive environments. |

|

|

Neoprene Neoprene is good at resisting UV light and weathering and provides reasonable protection with oils and petroleum. This material is frequently used in the refrigeration industry because it’s one of the best materials to resist ammonia and Freon. |

|

|

Nitrile Nitrile (Buna-N) is the most widely used general-purpose o-ring elastomer. This is because of the resistance to petroleum and oil products, superior compression set, tear, and abrasion resistance. However, it does not wear very well in sunlight or ozone. |

|

|

Silicone Silicone overall has notably beneficial properties to be used in a variety of ways. However, it is not commonly recommended for dynamic sealing applications due to its relatively poor tensile-tear strength and relatively low absorption resistance. Typically, this material is used in low friction and static applications in automotive. |

The Cutting Process

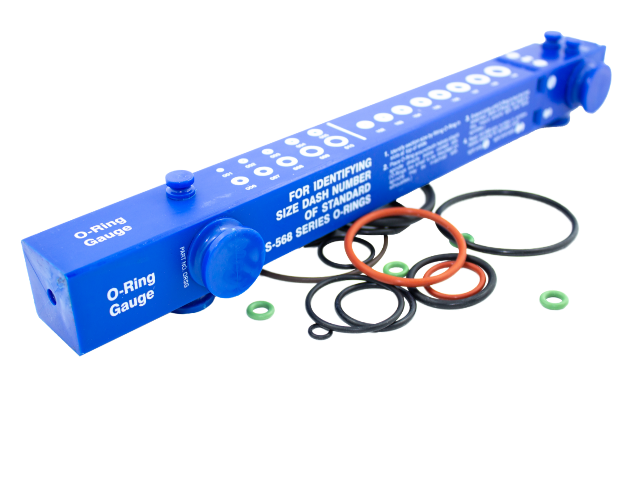

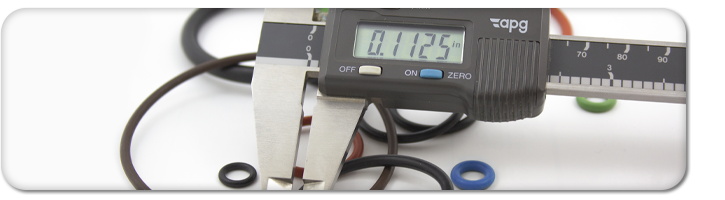

After selecting the cord, the next step in the vulcanizing process is to cut it to the desired length. In order to ensure the correct sized O Ring, two measurements from the list below are needed to accurately calculate the cut. All the o-ring cord is measured and cut in our warehouse by our vulcanizing team.

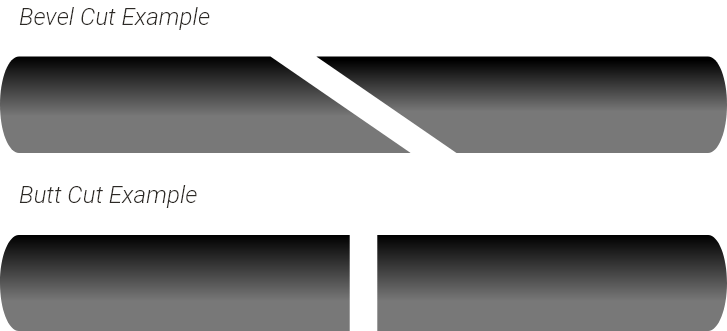

There are two types of cuts we provide here at APG, bevel and butt cuts. The most popular one is the butt cut, which is a 90 degree angle which is cut from top to bottom. The other cut is the bevel cut, also known as the skive cut, which is an angled cut that is believed to be stronger, depending of the use-case of the o-ring, because it has more surface area to be bonded.

Need a Custom O-Ring? Let us Help!

Vulcanization

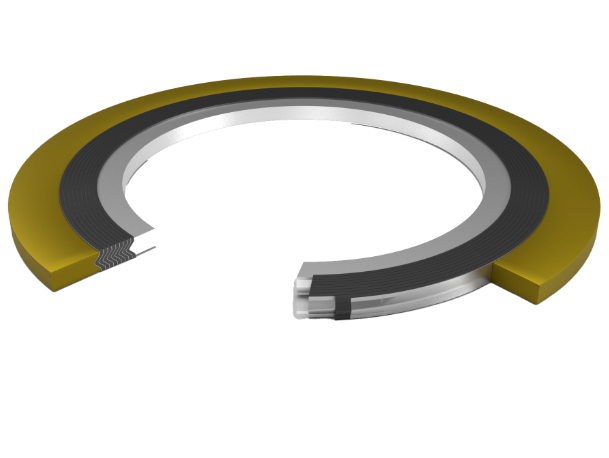

The Molds

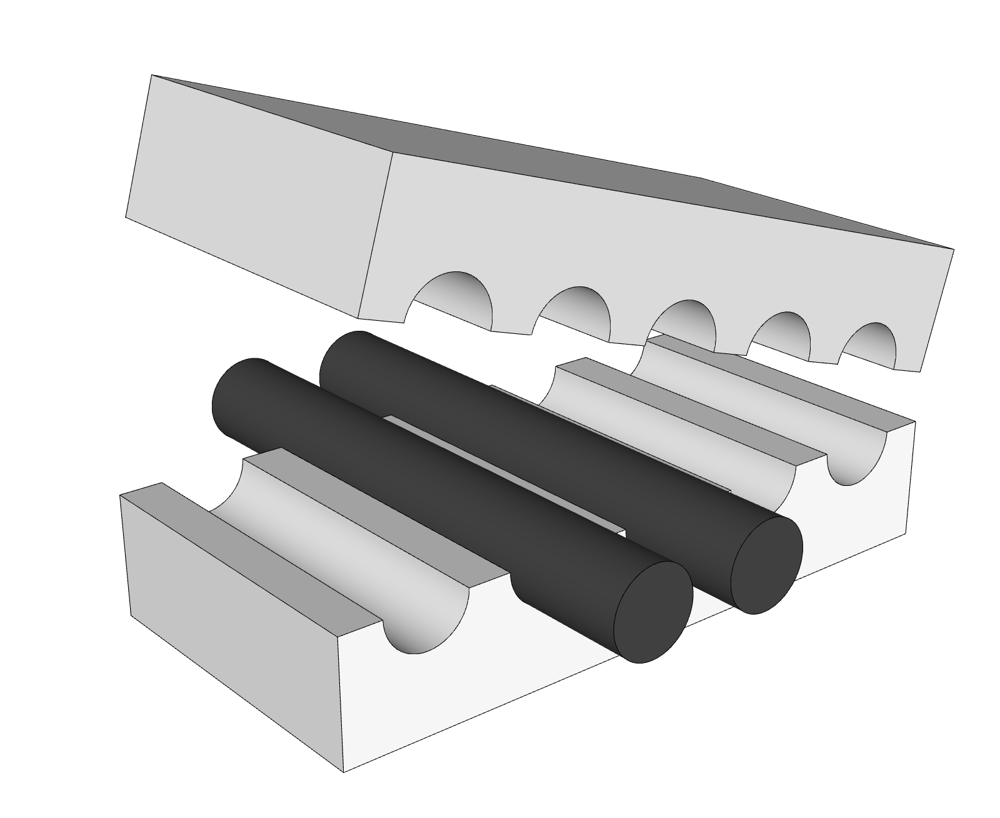

Currently our warehouse has over 20 vulcanization machines that can output approximately 2000 orings a day. APG uses a variety of molds that are fitted for each cross section of cord we have. The molds range in thickness, shapes, and can accommodate any size from a cross section of 1 inch or less. The mold is locked into place and the heating process begins. To get a more in depth look at our molds, interact with our 3D model.

The Process

After the cut has been made, we apply a special adhesive to each end of the cord. Different adhesives are used depending on the type of material. The material is then placed into the mold, also known as a die, once the temperature needed is reached. Each material has a different bonding temperature because the chemical makeup of each elastomer bonds differently. One of the main components in the vulcanization speed is dependent on the thickness of the cord that is being utilized. The thicker it is, the longer it will take to bond properly.

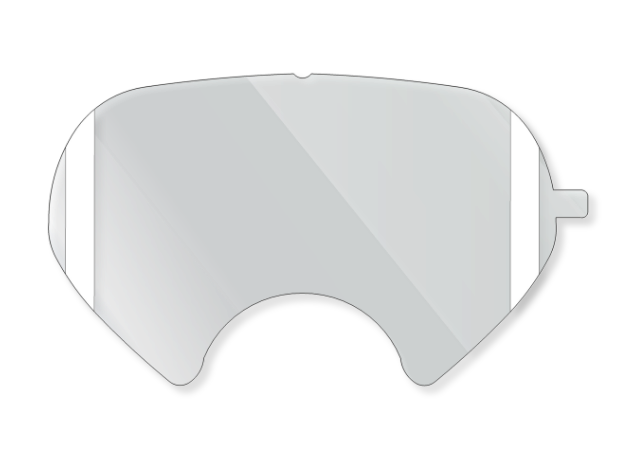

Quality Assurance

APG believes in providing the highest quality products, every-time. All our vulcanized products go through a rigorous inspection process to ensure product durability. If the O Ring is not up to our quality standards, we repeat the process until our standards are met and is ready to be shipped.

Understanding Sizing For AS568 And BS1806

If you have an o-ring that has failed and you require a replacement, while shopping you may be surprised to find out just how expansive the o-ring market is. If you are new to shopping for fluid sealing products you may feel you are reading a different language with different combinations...

How Weather Impacts O-Rings

The impact of weather needs to be taken into consideration when choosing the type of material that best suits your application. It is easy to overlook how weather conditions will impact o-rings that are outdoors, but failing to consider weather exposure can lead to premature failure of o-rings...

Get the latest updates on products, new knowledge base posts, and everything APG!