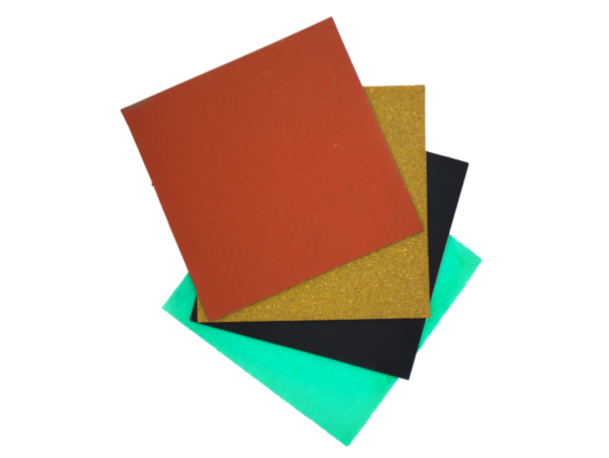

APG 0759CCE Medium Density Black Nitrile Extruded Closed Cell Sponge is a versatile and durable material that is suitable for a wide range of applications. Its tiny, sealed cells contain inert nitrogen gas, which helps to resist moisture and maintain its shape and structure. This makes it an excellent choice for use in wet or moist enclosures. In addition to its resistance to moisture, black nitrile closed cell sponge also has excellent sound and vibration dampening properties. It can be used to reduce noise and vibration in a variety of applications.

Product Specifications

| Properties | Typical Values |

| Color | Black |

| Firmness | Medium |

| Cell Type | Closed Cell |

| Backing Type | Plain |

| Temperature Range | -40ºF up to 200ºF |

| Brittle Point | -40ºF |

25% Compression Deflection | 5-9 psi |

25% Compression Resistance | 5-11 psi |

50% Compression Set | 25 (Maximum) |

Density, lb/ft3 (3/8" & higher) | 6-10 |

Density, lb/ft3 (1/4" & lower) | 6-12 |

Water Absorption, lb/ft2 | 0.1 (Maximum) |

Tensile Strength (Typical) | 75 psi (Minimum) |

Enlongation % (Typical) | 100% (Minimum) |

Flammability (FM VSS No. 302 | ASTN D 6576) | Pass |

Ozone Resistance (GM4486P) | Pass (No Cracking) |

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 7, Name = O-Rings, SeName = o-rings, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 1, SubCategory = O-Rings, SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0012944_o-rings_145.jpeg, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0012944_o-rings.jpeg, Title = Show products in category O-Rings, AlternateText = Picture for category O-Rings }, SubCategoryImageId = 25554, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0012944_o-rings.jpeg)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 3, Name = Industrial Couplings, SeName = industrial-couplings, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 2, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0026400_industrial-couplings_145.webp, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0026400_industrial-couplings.webp, Title = Show products in category Industrial Couplings, AlternateText = Picture for category Industrial Couplings }, SubCategoryImageId = 25611, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0026400_industrial-couplings.webp)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 2, Name = Sealing, SeName = sealing, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 3, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0026409_sealing_145.webp, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0026409_sealing.webp, Title = Show products in category Sealing, AlternateText = Picture for category Sealing }, SubCategoryImageId = 25613, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0026409_sealing.webp)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 10, Name = Gaskets, SeName = gaskets, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 4, SubCategory = Gaskets, SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0025556_footer-gasket.png, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0025556_footer-gasket.png, Title = Show products in category Gaskets, AlternateText = Picture for category Gaskets }, SubCategoryImageId = 25556, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0026410_gaskets.webp)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 4, Name = Industrial Glass, SeName = industrial-glass, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 6, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0026412_industrial-glass_145.webp, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0026412_industrial-glass.webp, Title = Show products in category Industrial Glass, AlternateText = Picture for category Industrial Glass }, SubCategoryImageId = 25615, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0026412_industrial-glass.webp)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 5, Name = Plastics, SeName = plastics, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 7, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0026406_plastics_145.webp, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0026406_plastics.webp, Title = Show products in category Plastics, AlternateText = Picture for category Plastics }, SubCategoryImageId = 25639, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0026406_plastics.webp)