FIX STIX epoxy is a hand-moldable, industrial-strength, steel-reinforced epoxy that plugs leaks, fills holes and cracks - and that will bond and repair anything made from steel. Conformable, safe and simple-to-use, this putty can be used by nearly any member of your team to quickly make a repair that can save several hours and significant money.

The Fix Stix EPOXY:

- Fully sets in 20 minutes

- comes ready to use - everything you need to repair the pipe is right there

- Pre-measured, non-toxic, solvent-free, and with little odor, so it's simple and safe to use

- Works underwater and over a wide temperature range

Product Specifications

| Item | Hand Moldable Epoxy |

| Set Time | 20 Minutes |

| Max Temperature | 300ºF |

| Compression Strength | 12,000 psi |

| Tensile Strength | 6,000 psi |

| Hardness | 80 (Shore D) |

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 7, Name = O-Rings, SeName = o-rings, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 1, SubCategory = O-Rings, SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0025554_o-rings.jpeg, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0025554_o-rings.jpeg, Title = Show products in category O-Rings, AlternateText = Picture for category O-Rings }, SubCategoryImageId = 25554, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0012944_o-rings.jpeg)

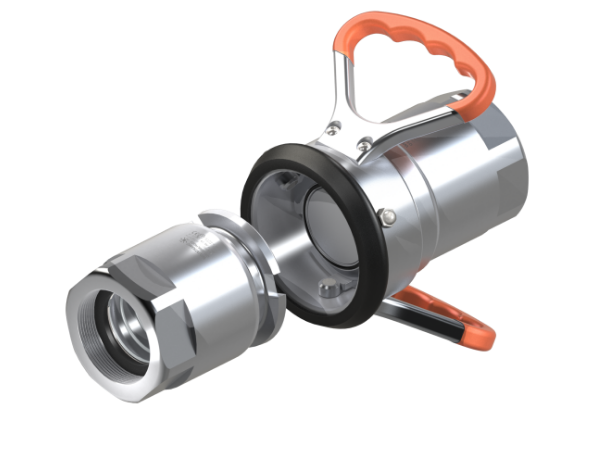

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 3, Name = Industrial Couplings, SeName = industrial-couplings, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 2, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0025611_footer-basic8.png, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0025611_footer-basic8.png, Title = Show products in category Industrial Couplings, AlternateText = Picture for category Industrial Couplings }, SubCategoryImageId = 25611, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0026400_industrial-couplings.webp)

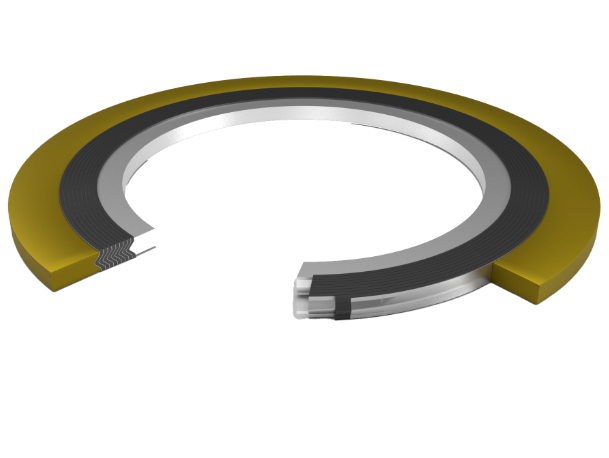

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 2, Name = Sealing, SeName = sealing, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 3, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0025613_footer-oring.png, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0025613_footer-oring.png, Title = Show products in category Sealing, AlternateText = Picture for category Sealing }, SubCategoryImageId = 25613, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0026409_sealing.webp)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 10, Name = Gaskets, SeName = gaskets, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 4, SubCategory = Gaskets, SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0025556_footer-gasket.png, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0025556_footer-gasket.png, Title = Show products in category Gaskets, AlternateText = Picture for category Gaskets }, SubCategoryImageId = 25556, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0026410_gaskets.webp)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 4, Name = Industrial Glass, SeName = industrial-glass, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 6, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0025615_flatfooter.png, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0025615_flatfooter.png, Title = Show products in category Industrial Glass, AlternateText = Picture for category Industrial Glass }, SubCategoryImageId = 25615, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0026412_industrial-glass.webp)

![CustomCategorySimpleModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 5, Name = Plastics, SeName = plastics, NumberOfProducts = , IncludeInTopMenu = True, SubCategories = System.Collections.Generic.List`1[Nop.Plugin.Misc.CustomFeatures.Models.Catalog.CustomCategorySimpleModel], HaveSubCategories = True, Route = , DisplayOrder = 7, SubCategory = , SubCategorySlug = , SubCategoryImage = PictureModel { CustomProperties = System.Collections.Generic.Dictionary`2[System.String,System.String], Id = 0, ImageUrl = https://callapg.com/images/thumbs/0025639_footer-headgear.png, ThumbImageUrl = , FullSizeImageUrl = https://callapg.com/images/thumbs/0025639_footer-headgear.png, Title = Show products in category Plastics, AlternateText = Picture for category Plastics }, SubCategoryImageId = 25639, InRawMaterials = False, RawMaterialsSubCategory = }](https://www.callapg.com/images/thumbs/0026406_plastics.webp)