-

-

February

2021

Sizing Your Rubber O-Rings

- oring

- orings

- o-ring

- o-rings

- rubber o-rings

- how to measure an o-ring

- apg

- american packaging and gasket

- apg rubber orings

- rubber orgins

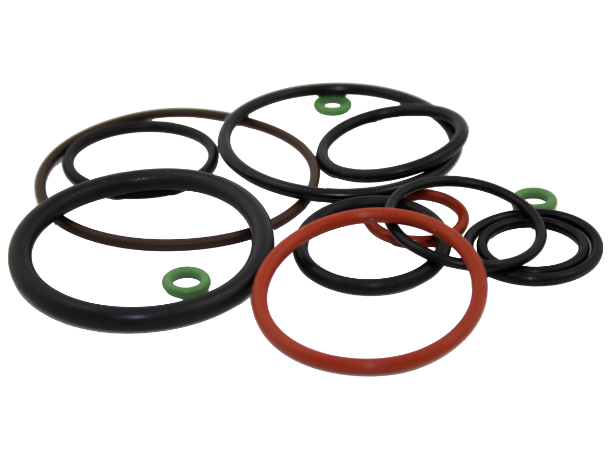

O-rings are bound to go out on you. When shopping for a replacement, you may be surprised to find out just how expansive the o-ring market is.

If you are new to shopping for fluid sealing products, you may feel you are reading a different language with various combinations of letters and numbers. Lucky for you, APG simplifies it for you!

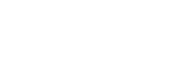

Step 1

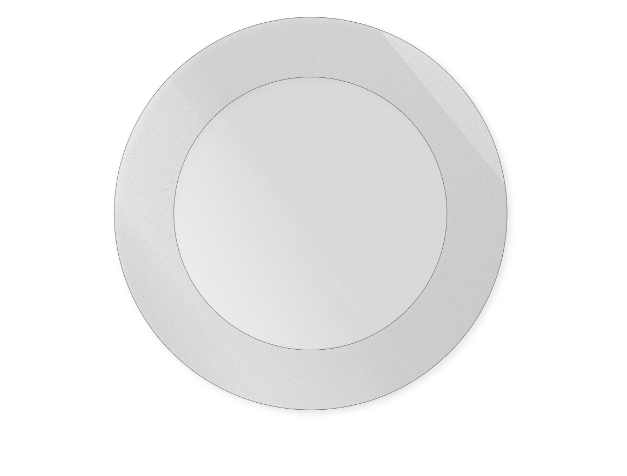

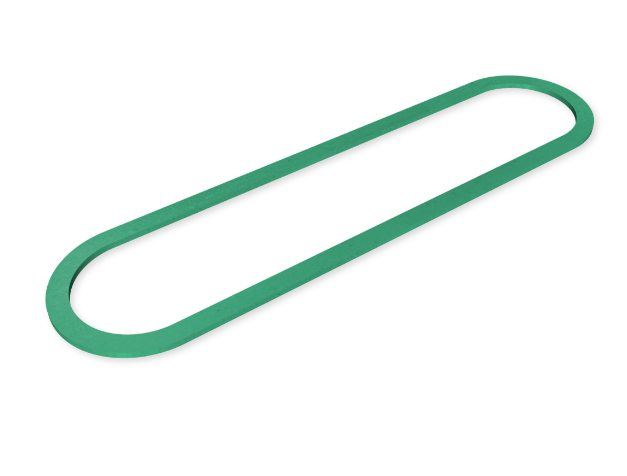

Inside diameter, or ID, measures the space inside the inner edges of the o-ring. This measurement determines how large the opening of your seal may be. Use a ruler to measure from one inside edge to another on a flat surface. Depending on the size, this measurement could be in millimeters or inches.

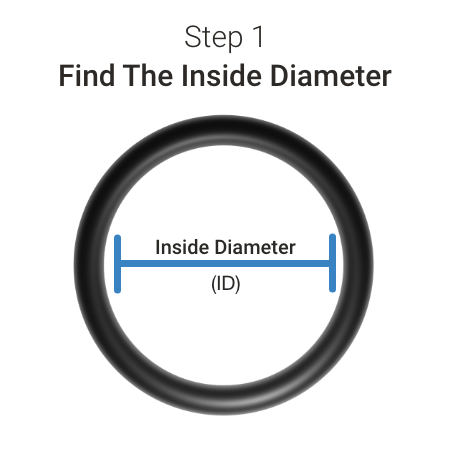

Step 2

Measure the Cross-Section. The cross-section, or CS, is the width or thickness of the seal. The best way to measure this is with a vernier caliper. Place the o-ring in the caliper without squeezing it to get this measurement. This measurement is essential as the width of the seal helps to determine the O-R's abrasion resistance, compression resistance, and volume well.

Step 3

Even if you are unfamiliar with o-rings, you know that every rubber material has a different hardness. The Shore A durometer scale measures rubber materials. With rubber, the harder the compound, the harder the durometer. Standard rubber compounds usually have a 70 Shore A hardness, but they can differ dependent upon the material and the application. APG can help you determine hardness if you are unsure.

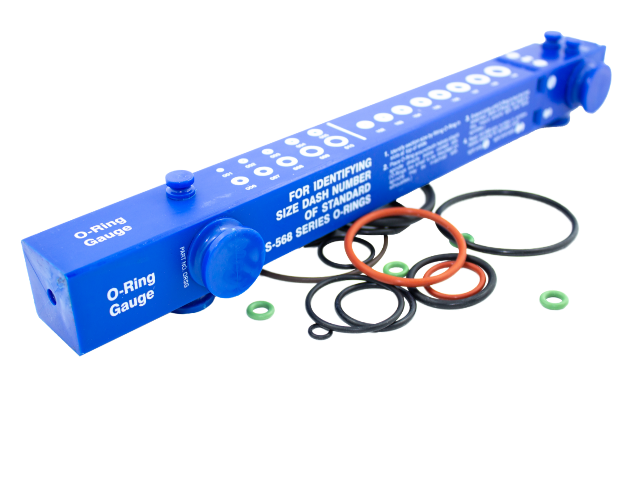

What Your Rubber O-Ring Measurements Tell You

Now that you have your ID and CS measurements for your o-ring, you can convert that information into standard o-ring language. O-rings are usually referenced by their ID and CS, and the type. For instance, if you have a 0.239 x 0.070 70 BN, that is a 70-shore ‘A’ hardness nitrile material o-ring. If you know your measurements, APG can help determine which rubber o-ring best suits your needs.

Shop APG O-Rings Now!

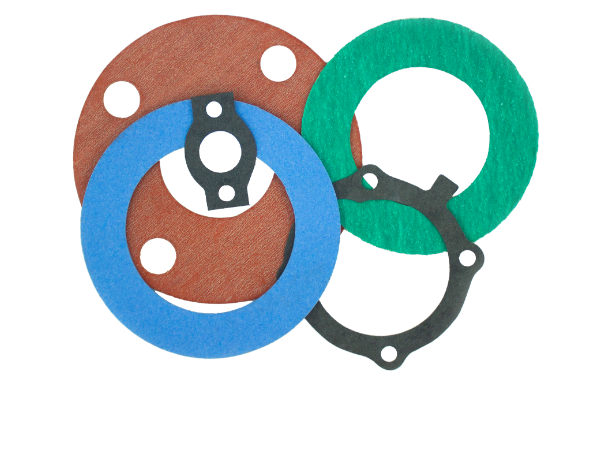

You can shop our rubber o-ring selection now! Since 1943, we have been providing high-quality o-rings, rubber gaskets, and other fluid sealing and conveyance products our customers need. Our selection features thousands of standard-size and vulcanized o-rings. Not sure which o-ring size is right for your application? Make APG your official o-ring store.

For a proper o-ring measurement,

Give us a call at 713-561-3309

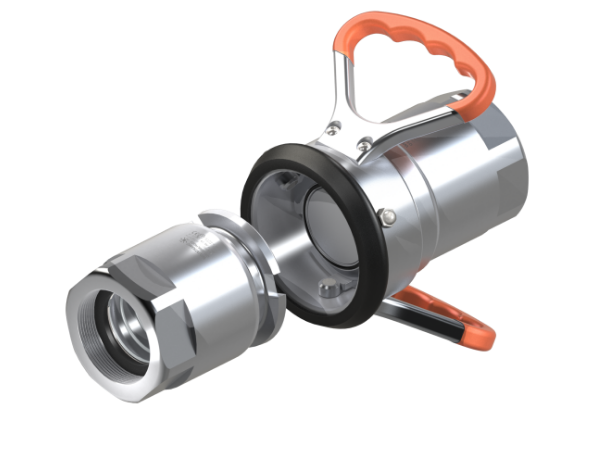

How To Install An O-Ring.

Once you have confirmed that your lubricant is safe for use with both your oring and your application, it is a good practice to double-check the o-ring size. The wrong size can lead to a damaged seal, poor performance, or a damaged system...

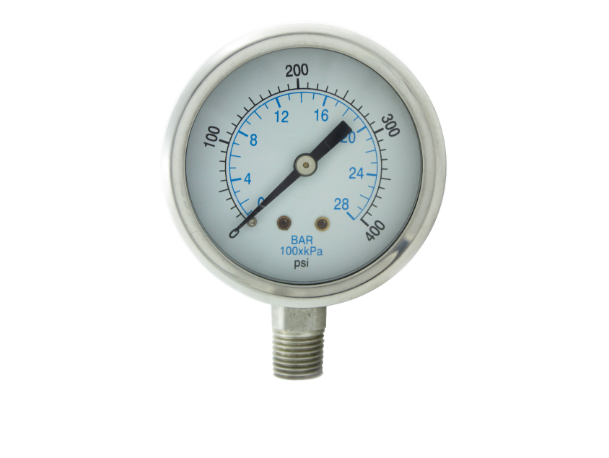

5 Factors To Choosing The Right O-Ring

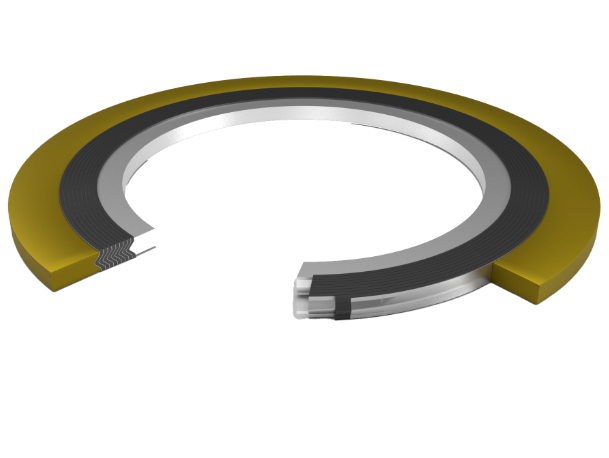

Backup rings are commonly installed with O-Rings to improve their performance. Backup rings are useful for many different reasons but the main reason is by blocking or reducing the extrusion gap. This prevents the O-Ring inside to be damaged or extruded causing...

Written By:

Stay Connected!

Get the latest updates on products, new knowledge base posts, and everything APG!