-

-

January

2022

Getting To Know: Smartflow Dry Break Couplings

- smartflow

- couplings

- dry break

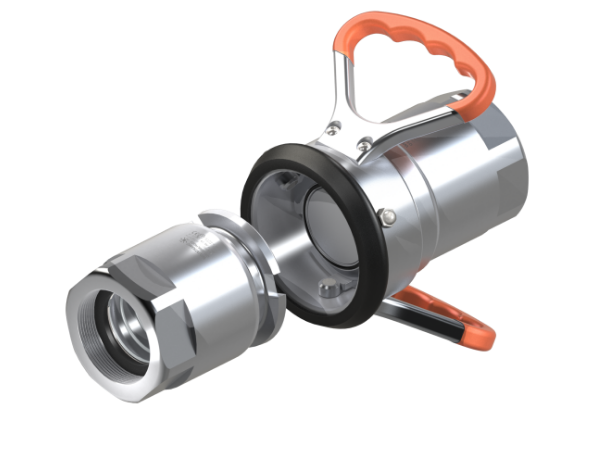

Smartflow’s range of dry-break couplings is aimed to aid the safe, efficient, and environmentally friendly transfer of fluids in safety-critical, aggressive environments. Making completely spill-free connections and disconnections with minimal parts and no additional valves required means the Smartflow systems can save the customer time and money.

Produced in the UK, these specialist couplings meet the challenges and solve problems for several industries all over the world: Oil & Gas, Petrochemical, Food & Drink, Road & Rail, Marine and anywhere where spillages need to be minimized or fluid transfer efficiency maximized.

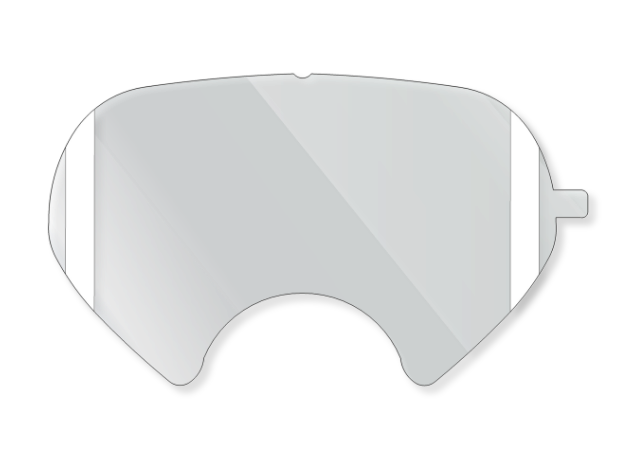

The couplings use a simple integrated poppet system, that activates as the female (Hose) unit is connected to the male (Tank) unit.

As the female coupling easily fits over the male adaptor, it is then twisted clockwise a 1/3 of a turn and locks in place - opening the integrated poppets in both halves and releasing the flow. The reverse anti-clockwise turn will unlock the couplings and instantly shut off the flow with zero (well very, very close to) spillage.

Efficiency and Productivity

No spills or waste as well as reduced downtime can be a huge benefit to process industries

Cost Saving

Cutting out waste from spillages could result in a big improvement in a company’s bottom line

Health and Safety

Eliminating spillages of hazardous fluids come with obvious health and safety benefits to the operator

Environmental

Protecting the environment is of course a key advantage of a spill-free system

Save The Waste

Smartflow Daybreak Couplings offer great environmental protection by stopping any leftover spillage from traditional couplings. These couplings are different than traditional couplings. They offer an easy twist on and off allowing a full start or stop of the liquid without leaks or left-over spillage. This benefits both the environment and your company by not having any wasted liquid materials.

Productivity and Efficiency Improvements

Product waste is commonplace for many industries using traditional couplings costing millions in lost revenue year over year. With Smartflow technology, product waste is a thing of the past. This means that you can save from product waste, have more to sell, and create less downtime increasing overall productivity.

In chemical and process industries, safety is taken very seriously. However, it is common for small leaks and spills to happen. With our dry break couplings, health and safety were the primary focus in the design of the product. Slips and trips cause 15% of all accidental deaths and lead to the majority of general industry accidents. Since all process fluids are contained, there is zero clean-up necessary. This means accidental injuries and falls because of spillage on the floor will be minimized keeping your employees happy and safe.

Smartflow couplings are designed with a fresh approach to keep the cost of the coupling efficient through simplicity and modern manufacturing techniques. Quality of materials is a priority for Smartflow and this was kept top of the list throughout the design process. Smartflow couplings are interchangeable with other dry-break couplings on the market that conform to TEAM SPEC and NATO STANAG 3756 standards.

Speak with an expert to learn even more about these couplings or if you are ready, shop now.

Stay Connected! Sign up to get the latest updates and discounts from APG by filling out the form below