-

-

July

2021

What is Durometer?

- durometer

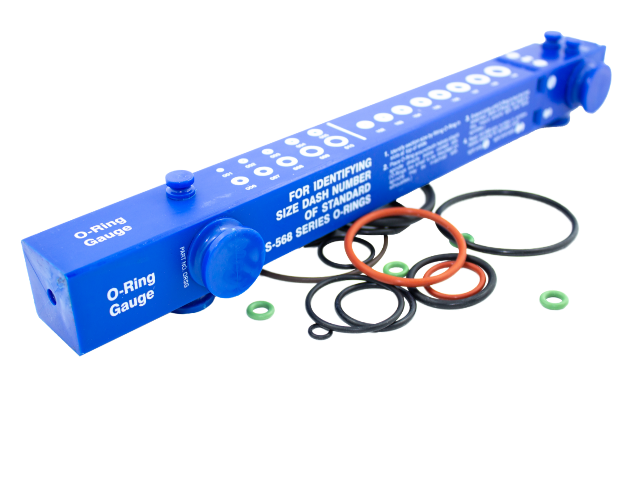

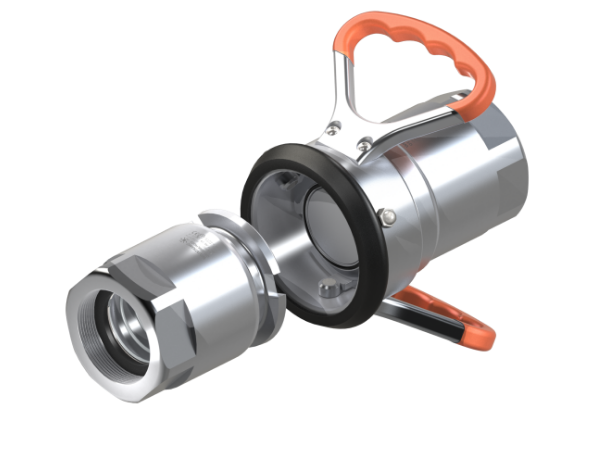

- o-rings

- shorea

- shore

- hardness

- nitrile

- silicone

- aflas

Updated October 7, 2021

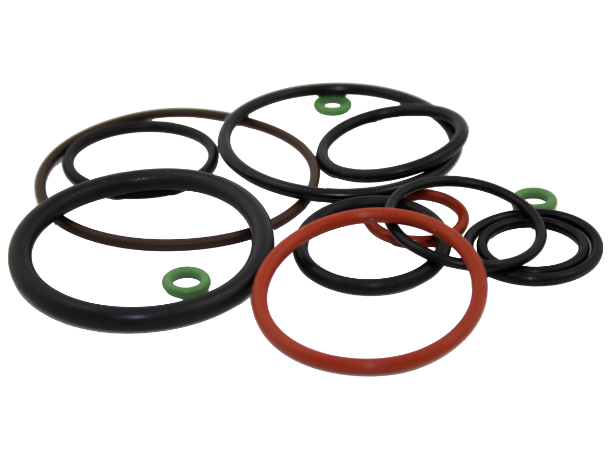

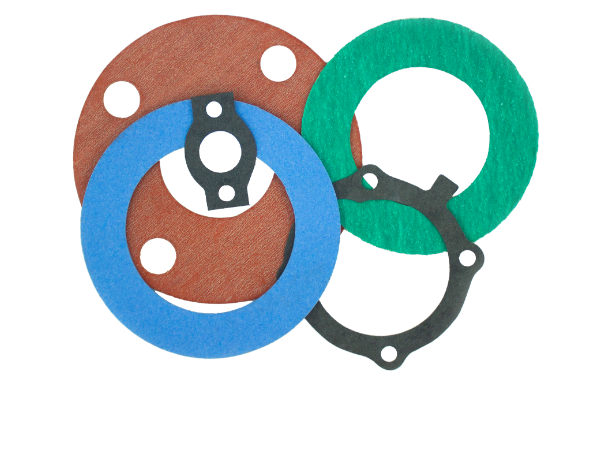

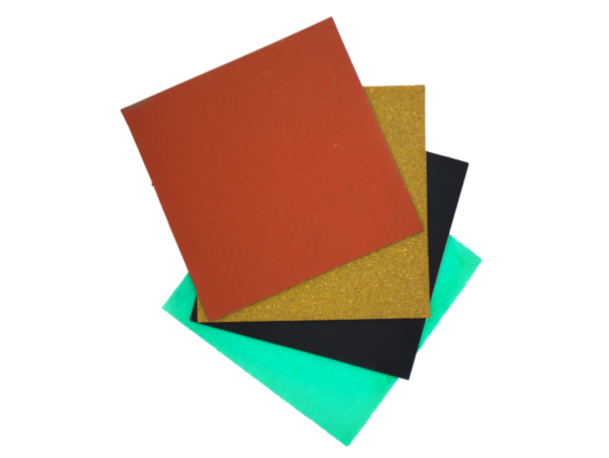

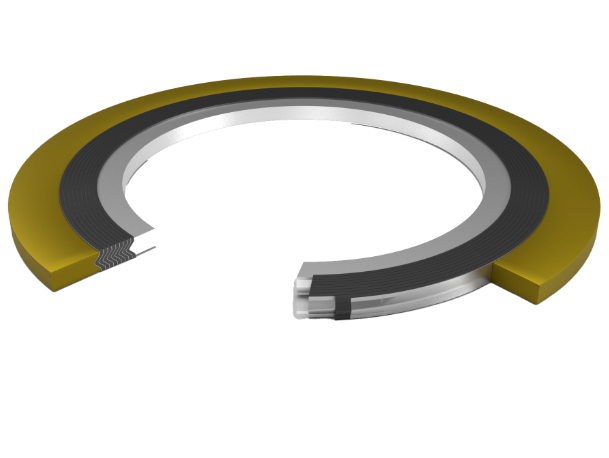

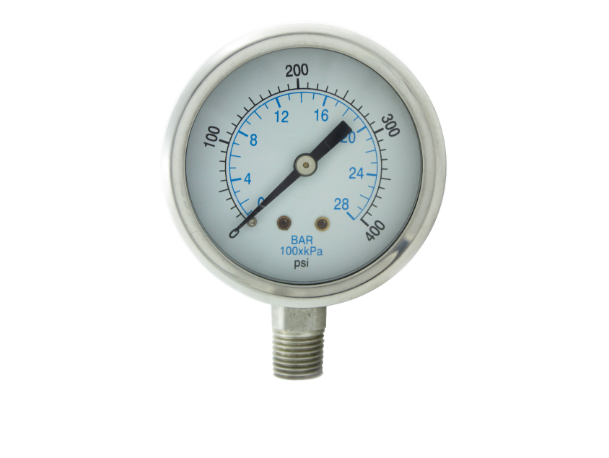

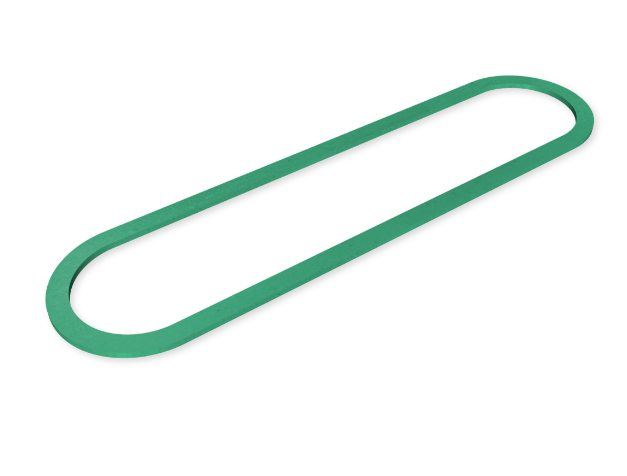

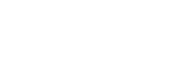

The durometer is a measurement of the hardness of a piece of rubber. However, there are a few different scales the industry uses to measure the durometer of an object. The most popular way is the Shore A durometer scale. Shore A is the way APG measures its materials to ensure the most accurate hardness rating possible. A 70 Shore A durometer is the most common level of hardness as it is the most practical for many O-Ring applications. 70 durometer is often known as the standard since it is not too hard and it stretches enough for most applications. For example, a 60 durometer is softer than a 70, and a 90 is hard than both of those. If there is a certain durometer you are looking for, please contact APG or go to our website to filter through all our durometers.

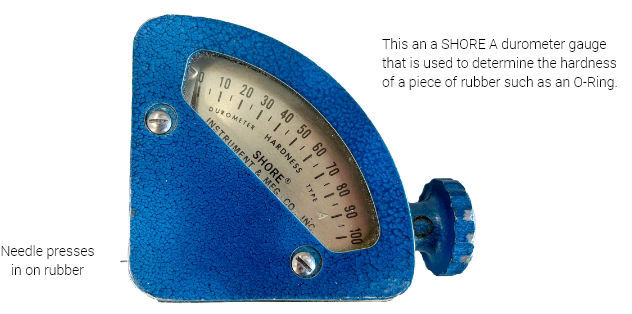

Shore A & Shore D

Shore Durometers are broken up into two different units of measurements. Shore A, which measures softer materials such as rubber, and Shore D, which measures harder materials such as hard rubbers and hard plastics. Since Shore A measures softer materials the tool has a flatter tip to determine the softness, while Shore D uses a pointed tip to measure the hardness of harder materials.

There are in fact other standards of rubber elastomer hardness such as the ASTM standard and IRHD standard. However, the SHORE standard is recognized as the global standard in measuring the hardness of materials.

There are in fact other standards of rubber elastomer hardness such as the ASTM standard and IRHD standard. However, the SHORE standard is recognized as the global standard in measuring the hardness of materials.

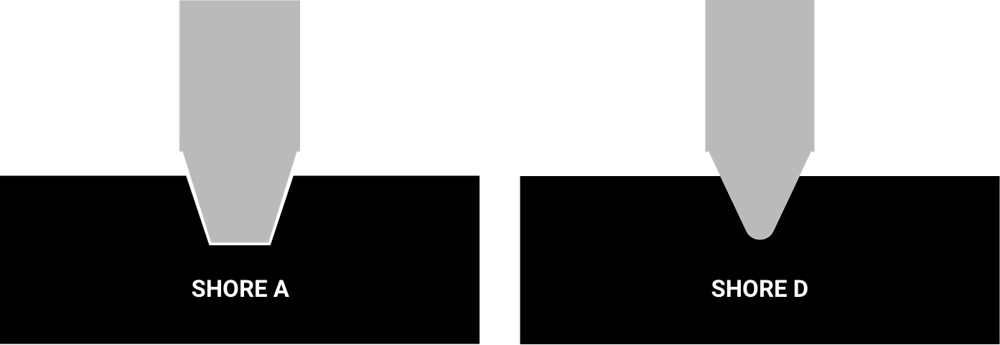

Durometer Of Different Objects

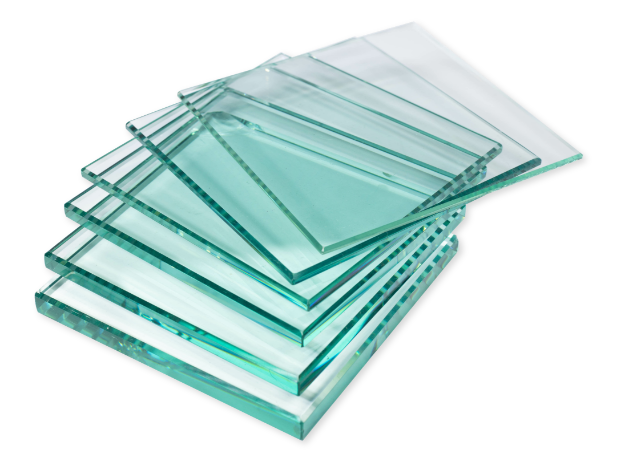

Durometers vary depending on materials and the type of application it will be used on. Depending on the job, some applications will require a softer material over a harder material. Softer materials such as rubber bands tend to stretch a bit more while harder materials are more ridged such as PTFE that can hold its shape better. Then there are things right down the middle at a 70 durometer. A 70 durometer is considered the average level of hardness for most O-Rings and are widely used in many industries. How hard is 70 durometers though? Below you will see a chart of everyday objects and their durometer.

Get To Know Materials: PTFE

Aflas® is unique compared to other rubber materials as it has a wide range of resistive properties. Such as high temperatures, chemicals, electrical, and petroleum. This being said you can easily apply this to many factors such as down holes, general steam, marine...

How Weather Impacts O-Rings

The impact of weather needs to be taken into consideration when choosing the type of material that best suits your application. It is easy to overlook how weather conditions will impact o-rings that are outdoors, but failing to consider weather exposure...

Stay Connected!

Get the latest updates on products, new knowledge base posts, and everything APG!