-

-

July

2021

The Shelf Life of Elastomers

- age

- elastomers

- rubber

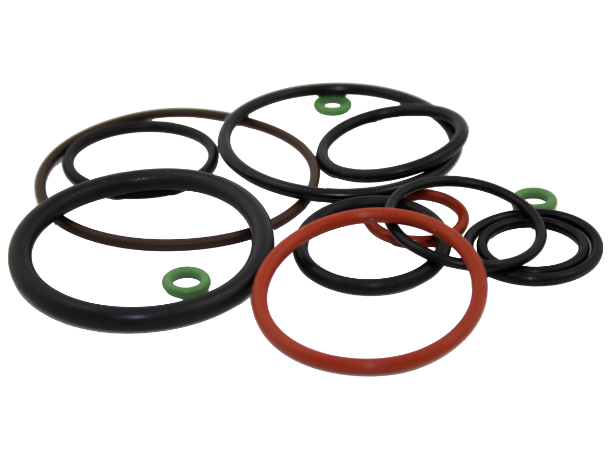

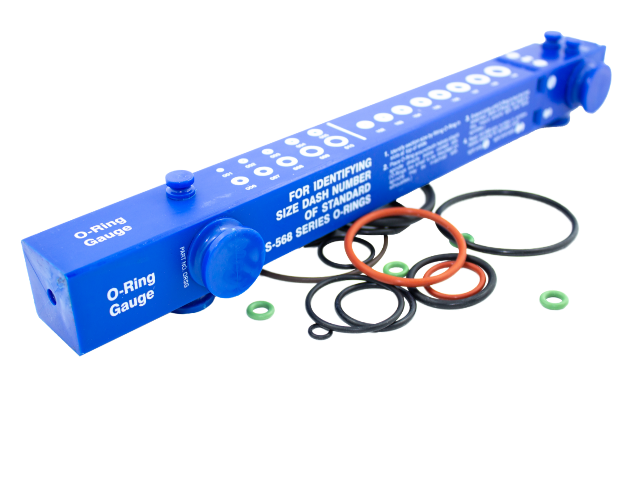

- orings

- warehouse

- safety

- storage

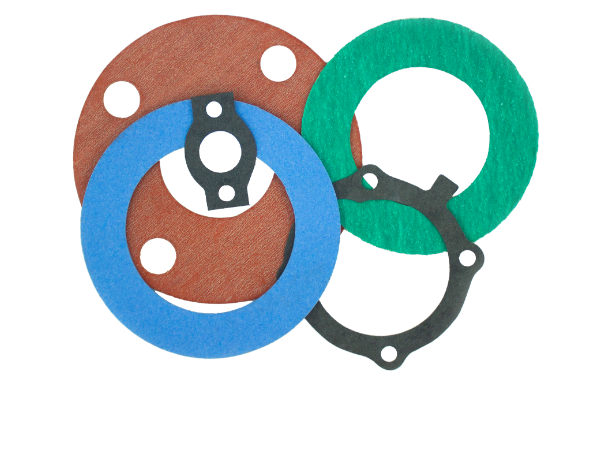

- gaskets

Updated Dec 2023

Have you ever wondered about the shelf life of elastomers? As a commonly used material in various industries, knowing how long elastomers can last before they start to degrade or lose their properties is crucial. In this blog post, we'll dive into the world of elastomers and explore the factors that affect their shelf life, as well as tips on how to extend their lifespan. Whether you're a manufacturer, engineer, or simply curious about the material, read on to learn more about the shelf life of elastomers.

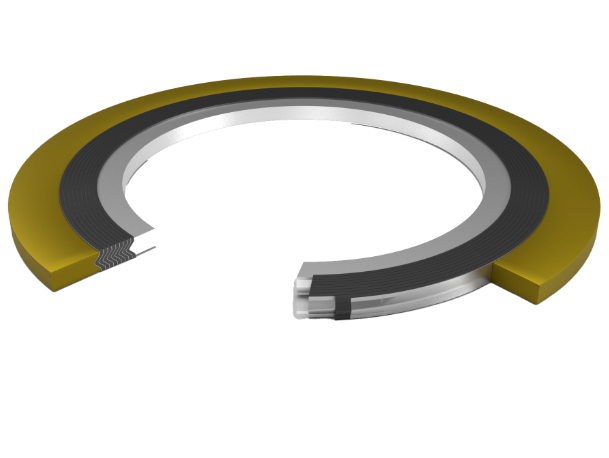

Elastomers are a versatile material with various applications across different industries, ranging from automotive to aerospace, medical, and consumer goods. However, like most materials, elastomers have a limited lifespan and can degrade over time, affecting their performance and reliability. The shelf life of elastomers refers to the duration for which they can be stored without significant changes in their physical and mechanical properties.

Several factors influence the shelf life of elastomers, including the type of elastomer, storage conditions, temperature, humidity, exposure to light, and exposure to chemicals. For instance, some elastomers are more resistant to heat, while others may be susceptible to oxidation or degradation when exposed to UV radiation or certain chemicals.

Temperature

O-Rings and other elastomers should be stored at a proper temperature that should NEVER exceed 120ºF but is recommended to stay below 100ºF at all times. Any heat sources such as furnaces, fires, boilers sunlight, and radiators should not be near any elastomer. Temperatures can affect the stability of any rubber elastomer. In high temperature situations, these rubber elastomers can deteriorate quickly as a major temperature change could cause a chemical change over a long period of time. These changes are irreversible and can change the strength and integrity of the elastomer. Exposure to cold weather can cause the rubber to lose its elasticity. Which can cause the o-ring to lose its compression set, become less flexible, and can even become brittle and break off. As the compression set worsens, the o-ring cannot go back to the original size. To learn more about the effects of temperature on O-Rings, read ouot knowledge base blog about how weather effects elastomers.

Light, Radiation and O-Zone

Ozone has an impact on the polymer chain, especially at the corner or edges of the seal where there is more stretch occurring. When the polymer chain is disrupted the o-ring will usually form a crack, leading to leakage and potential catastrophic malfunction of the whole application. High voltage equipment, combustable gases, and anything that generates ozone, heat, or radiation should not be near any elastomers. Elastomers have much longer shelf life if lighting conditions are met. O-Rings and other elastomers should be protected from all light sources especially sunlight, UV light, and super bright direct light sources.

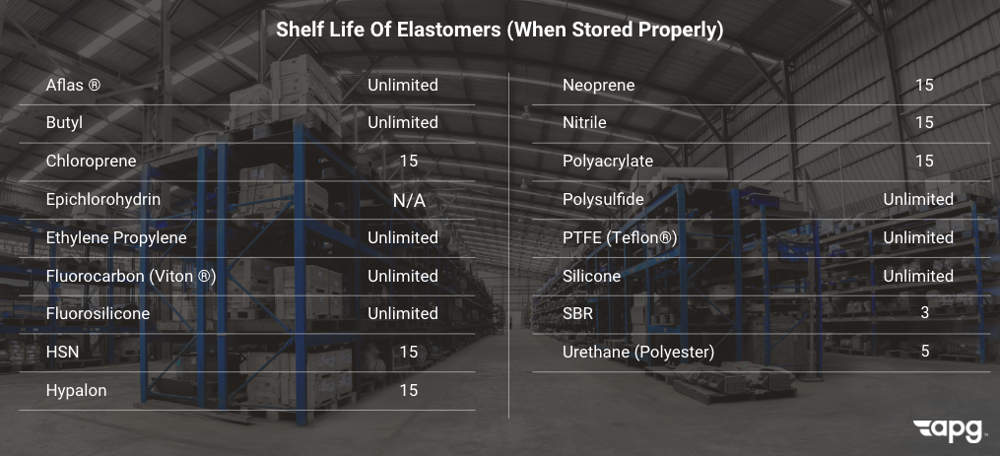

About This Chart

APG uses the most accurate data covered by the Military Material specifications. Although when properly stored, elastomers have been known to shelf age for very long periods, the following chart indicates the generally accepted age resistance for various elastomers (from MIL-HDBK-695).

Suggested Storage Conditions

O-Rings should be stored in clean & dry containers away from ozone, sunlight, UV light, and radiation. The temperature should never exceed 120ºF. For example, Aflas and Silicone can last an infinite amount of years while Nitrile can last 15 years and Urethane can last 5 years.

Storing elastomers wrong could lead to premature failure of systems when using them of any application. Learn the common causes of o-ring failure so you can prevent damage before it occurs.

Want More Info?

APG uses the research of MIL-HDBK-695 and AS1933 to determine the shelf life of our elastomers. The chart above shows all the elastomers we have, and their respective shelf life as determined with that research. We recommend following our guidelines to storing O-Rings as this will ensure the longevity of the rubber elastomer. If you do have any questions, please Contact Us or look at our Knowledge Base for up to date articles of our elastomers