-

-

August

2021

Which O-Ring Works Best For Your Industry?

- industries

- industry

- o-rings

- o-ring

- oring

- elastomers

- silicone

- fluoroelastomer

- viton

- polyurethane

- urethane

- ethylene propylene

- epdm

- hydraulic

- semiconductor

- pharmaceutical

- technology

- water systems

- food

- beverage

- dairy

- buna

- medical

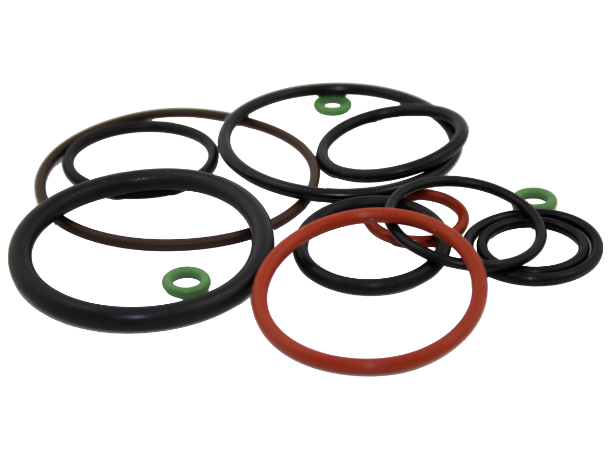

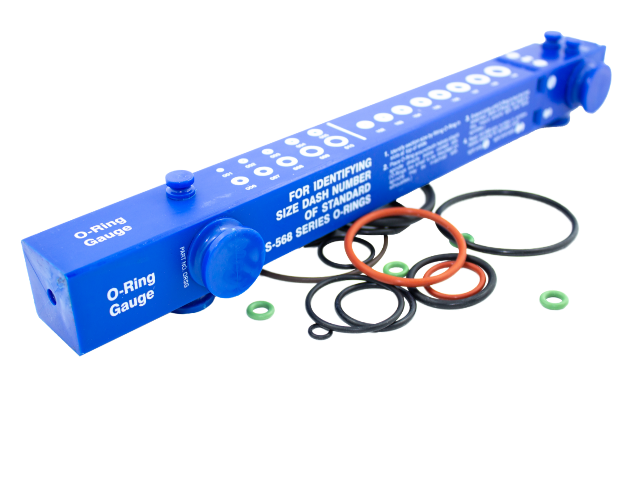

O-Rings are one of the most important unseen inventions in human history. Alone they are just round rubber rings that come in various sizes however when compressed between two different parts, they create a water-tight seal that locks in fluids and gases. Different industries use these O-Rings in a variety of applications. Selecting the right material, size, and durometer can be a stressful and daunting task since finding the right combination is critical to the longevity of the application.

Silicone

Silicone overall has notably beneficial properties to be used in a variety of ways. However, it is not commonly recommended for dynamic sealing applications due it its relatively poor tensile-tear strength and relatively low absorption resistance. With a temperature range of -80ºF to 450ºF and resistance to many acids, UV light, ozone, heat, and water, silicone can be used in a variety of industries such as:

- Medical

- Pharmaceutical

- Water Systems

- Technology

- Semiconductor

Nitrile

Nitrile (Buna-N) has great resistance to petroleum and oil products, superior compression set, tear, and abrasion resistance. However, it does not wear very well in sunlight or ozone. Nitrile isn’t known to have the greatest chemical resistance but is known to have excellent petroleum and oil resistance. Because of Nitrile’s many good qualities, it has been deemed a general-purpose elastomer and has become one of the most widely used O-Ring materials. Nitrile is used in many industries such as:

- Hydraulic Systems

- Oil, Gas, Petroleum

- Water Systems

- Automotive

- Military

- General Use

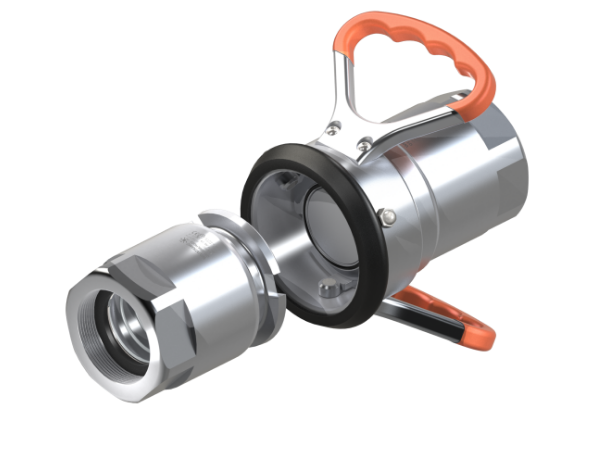

Fluorelastomer (Viton)

Fluoroelastomer (Viton®) performs well in many different environments such as a variety of oil and petroleum products, high vacuum situations, ozone, weather, high temperatures, and strong acids. This material is commonly used to seal leaks, valves, or pumps. Fluoroelastomer (Viton®) has a high resistance to petroleum products as well as a super-low compression set. This makes them a good choice for a variety of industries such as:

- Chemical Processing

- Automotive

- Aerospace

- Automotive

- Oil, Gas, Petroleum

Ethylene Propylene

Ehtylene Propylene is a great material to be used in many different fields, especially when it comes to commercial aircraft. It offers great ozone, water, steam, acid, and base resistance. However, it lacks in petroleum sealing. Temperature ranges -65ºF to 300ºF. Ethylene Propylene carries a special resistance to Skydrol® fluids which are commonly used in commercial aircraft hydraulic systems. Ethylene Propylene offers great resistance for ozone, water, steam, acids, and alkalies. This material is not great with petroleum sealing, however, they are wonderful in these industries:

- Pharmaceutical

- Medical

- Food Grade

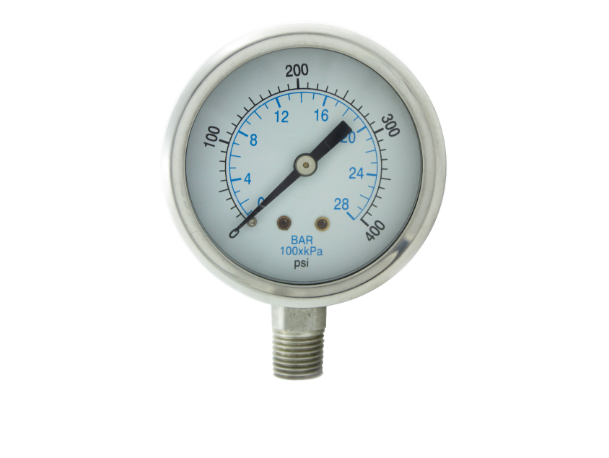

Urethane (Polyurethane)

Urethane overall is a great material that has a lot of resistive properties such as hydraulic fluids, oil, grease, chemicals, ozone, and oxygen. Meanwhile, it can endure high pressures and is resistant to cracking and cuts. Urethane is resistant to weathering, ozone, and oxygen. This material also has good resistance to oil and petroleum products and hydrocarbon fuels. This material is frequently used in:

- Firearms

- Fluid Transfer Systems

- Hydraulics

- Pneumatic Systems

- Cylinders

- Valve Systems

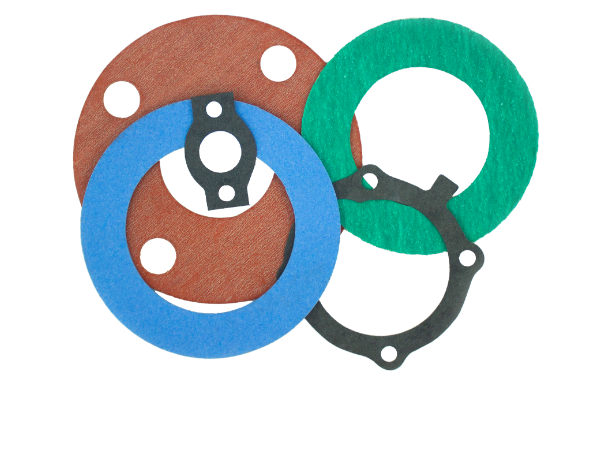

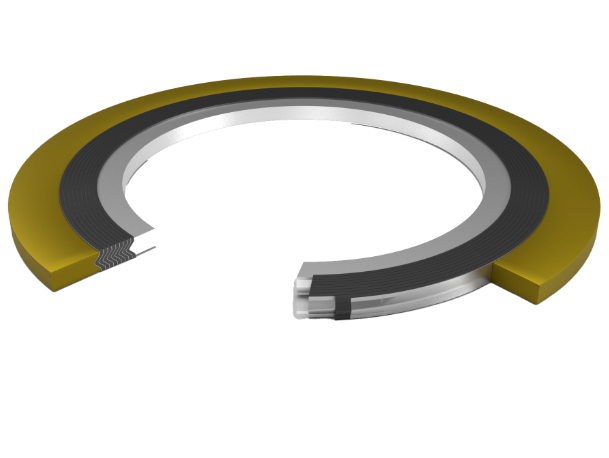

Elastomers can serve a variety of uses in an unlimited amount of industries. From aerospace, fluid supplies, food and dairy, industrial hydraulics, marine, medical, oil, gas, petroleum, pharmaceutical, and semiconductor, there are a vast number of industries to be served. However, if not stored properly, any elastomer will fail with ease. Check out our Knowledge Base blog to see how to properly store elastomers to ensure their longevity. With custom sizes, a variety of materials, and great customer service, let APG be your fluid sealing and conveyance provider. Contact Us or look at our Knowledge Base for up to date articles of our elastomers.

How Weather Impacts O-Rings

The impact of weather needs to be taken into consideration when choosing the type of material that best suits your application. It is easy to overlook how weather conditions will impact o-rings that are outdoors, but failing to consider weather exposure...

Five Factors To Choosing The Right O-Ring!

You can have the most innovative and high-tech equipment, but if you don’t have the right o-ring in place it may be rendered useless. The importance of choosing the right o-ring for any application should never be underestimated...

Written By:

Stay Connected!

Get the latest updates on products, new knowledge base posts, and everything APG!