-

Sealing

-

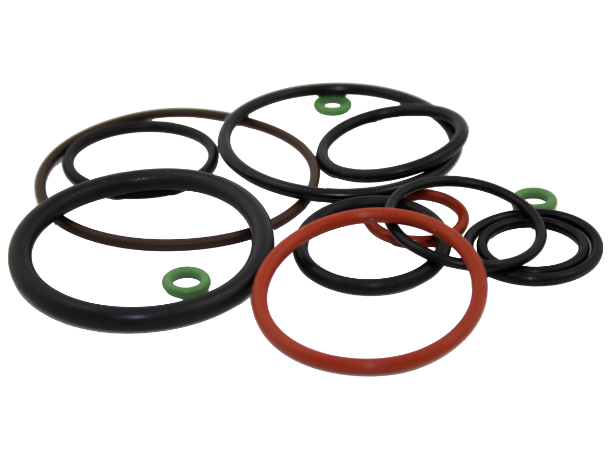

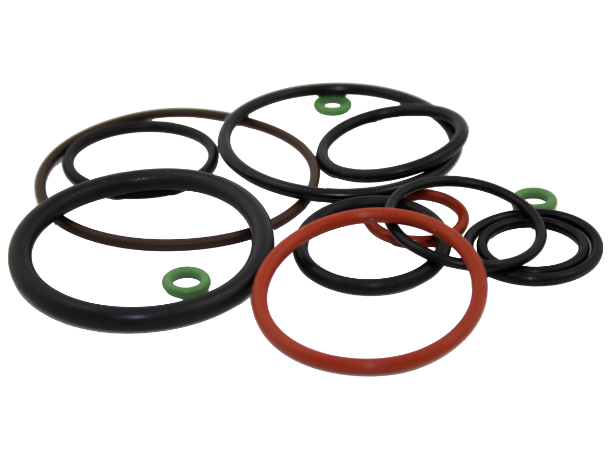

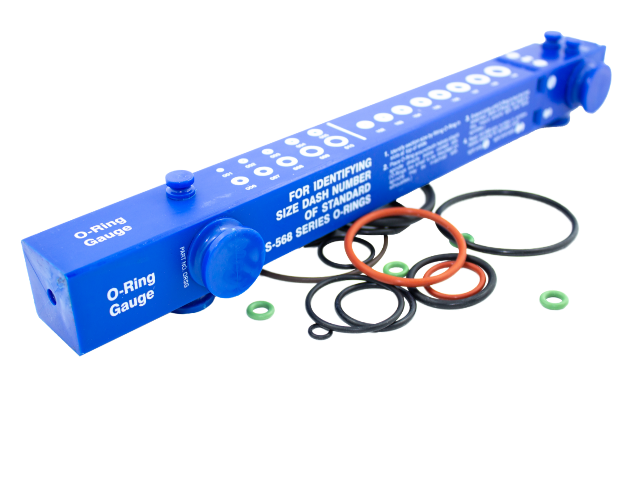

O-Rings

-

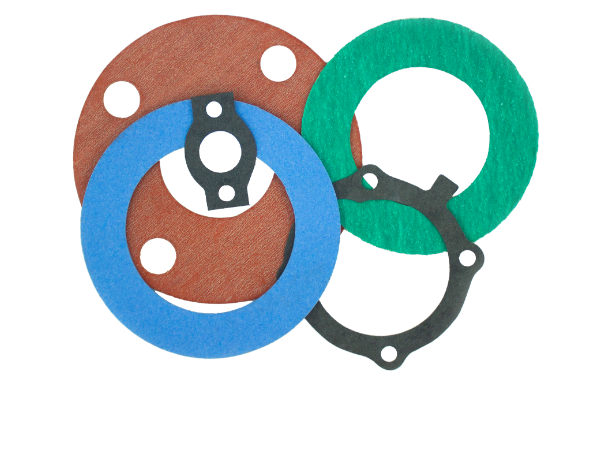

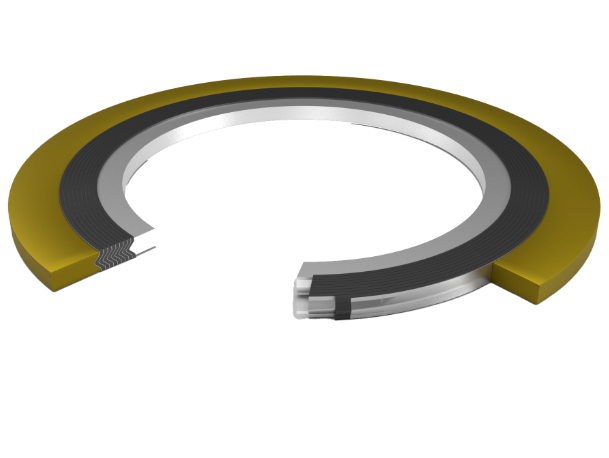

Gaskets

-

Seals

-

Packing

-

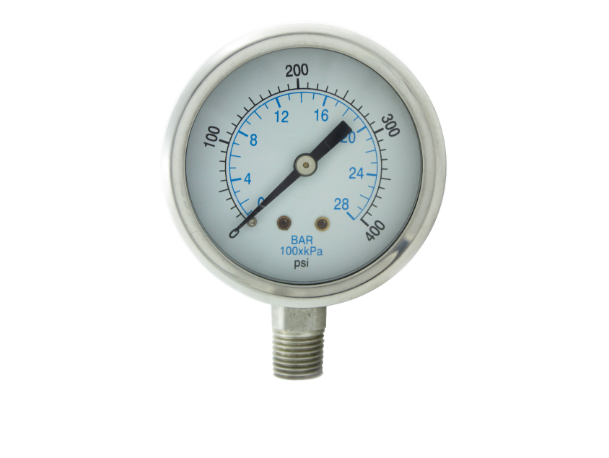

Accessories

-

-

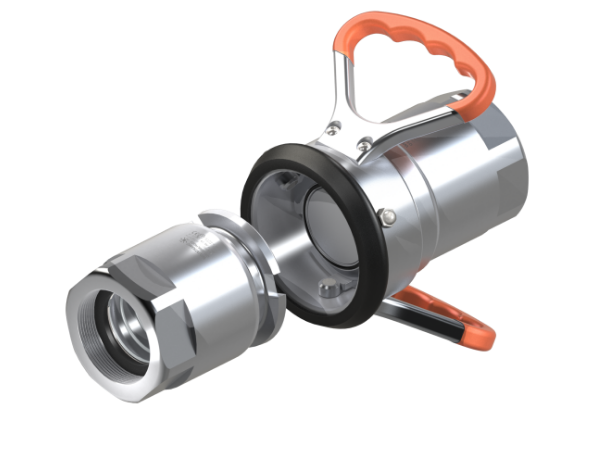

Industrial Couplings

-

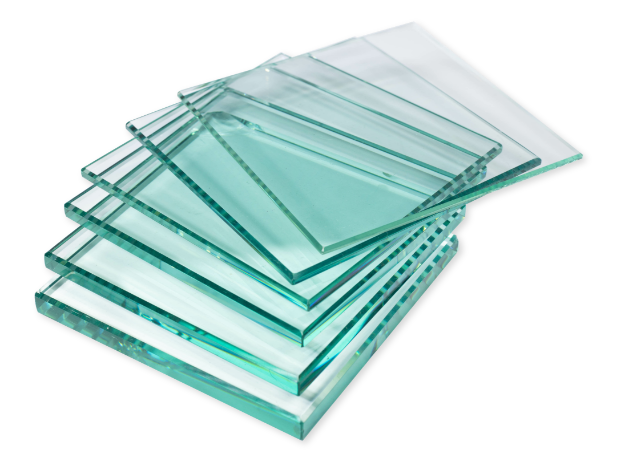

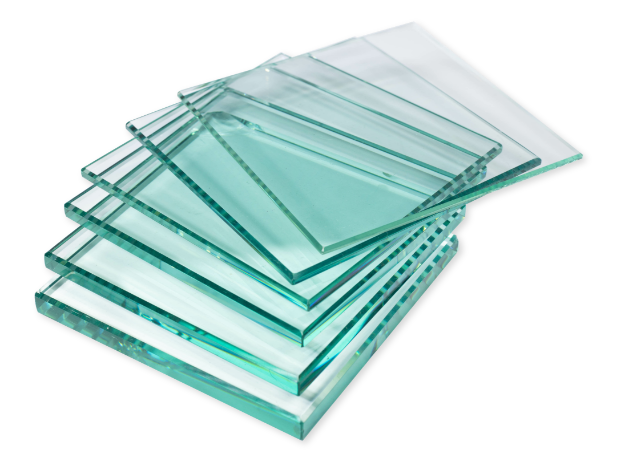

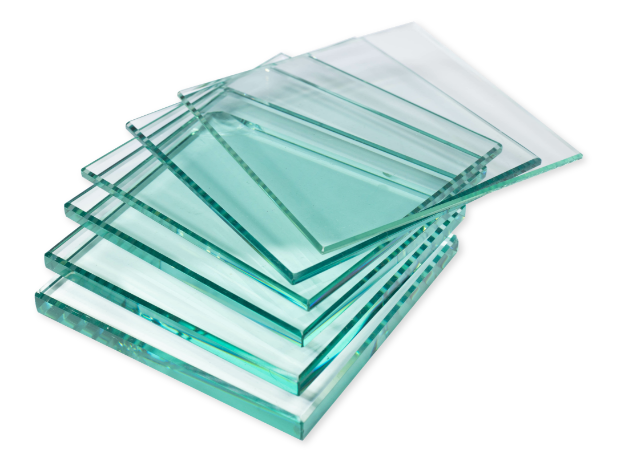

Industrial Glass

-

Industrial Glass

-

Accessories

-

-

Plastics

-

Personal Protective Equipment

-

Industrial Plastic

-

-

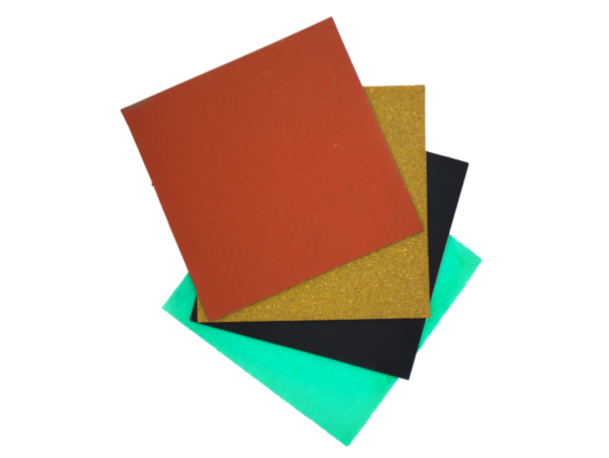

Raw Materials

-

Sealing

-

Industrial Plastic

-

- Home page

-

Sealing

-

O-Rings

-

Gaskets

-

Seals

-

Packing

-

Accessories

-

-

Industrial Couplings

-

Industrial Glass

-

Industrial Glass

-

Accessories

-

-

Plastics

-

Personal Protective Equipment

-

Industrial Plastic

-

-

Raw Materials

-

Sealing

-

Industrial Plastic

-

-

Excess & Obsolete

- New products

- Search

- My account

- Blog

- Contact us

Embarking on any engineering or manufacturing endeavor, one quickly encounters the humble yet indispensable o-ring. These small, unassuming loops of elastomeric material serve as unsung heroes, providing crucial seals in a myriad of applications, from aerospace to automotive industries. Yet, their effectiveness hinges on a complex web of standards and specifications. At the heart of this web lies the AS568 standard, a meticulously crafted set of guidelines that ensures uniformity and interchangeability across the o-ring landscape.

In this blog post, we delve into the world of o-ring standardization, exploring the significance of the AS568 standard and its pivotal role in engineering precision, quality control, and seamless integration across diverse manufacturing processes, as well as the British standard, BS1806.

At the heart of o-ring design and production lies the AS568 standard. This meticulously crafted set of guidelines serves as the backbone of the o-ring industry, providing engineers and manufacturers with a systematic approach to sizing and specifications. With a catalog boasting 394 different sizes, the AS568 standard ensures that there's a perfect fit for virtually any application, from hydraulic systems to medical devices.

Engineering Precision:

Imagine a hydraulic system powering a commercial aircraft or a delicate medical device saving lives – both scenarios require precise seals to function flawlessly. The AS568 standard provides engineers with a systematic approach to o-ring sizing and specifications. This meticulous attention to detail ensures that each o-ring fits its intended application perfectly, contributing to the overall precision and reliability of the system.

Quality Control:

In the realm of manufacturing, consistency is key. The AS568 standard serves as a beacon of reliability, guiding manufacturers in producing o-rings with uniform dimensions and properties. By adhering to these stringent guidelines, companies can implement robust quality control measures, minimizing variations and defects in their products. This commitment to quality not only enhances the performance of individual components but also instills confidence in the reliability of the systems they support.

Seamless Integration:

One of the greatest challenges in manufacturing is ensuring compatibility across diverse components and systems. Here, standards like AS568 and BS1806 play a pivotal role. By establishing uniform dimensions and specifications, these standards facilitate seamless integration of o-rings into various applications, regardless of the manufacturer. Whether it's a hydraulic pump in a factory or a valve assembly in a nuclear power plant, engineers can trust that o-rings manufactured to these standards will fit and function as intended, minimizing the risk of leaks and malfunctions.

With this bit of history in mind, you may still be curious how you calculate o-ring formulas.

To calculate the outside diameter or OD, you use this simple formula:

2(CS) + ID = OD

If you have the OD and you need to find the ID you can use this formula:

OD-2(CS) = ID ACtu

Across the Atlantic, the British Standard BS1806 stands as a testament to engineering excellence. Similar to AS568, BS1806 provides engineers and manufacturers with a comprehensive framework for o-ring design and production. While it may have its own unique specifications and classifications, its goal remains the same – to ensure the reliability and performance of o-rings in diverse applications. This standard also includes all of the 5 main cross-section groups in the AS568 and sizes that are between AS568 sizes. The BS 1806 standard size guide has been replaced by the BS ISO 3601, although BS1806 standard is still heavily referenced and relevant.

What Size Rubber O-Rings Do You Need?

You have an o-ring that is worn out and needs to be replaced so you shop around online and quickly become overwhelmed with options. There are thousands of different standard sizes of o-rings to choose from and custom...

How Weather Impacts O-Rings.

Backup rings are commonly installed with O-Rings to improve their performance. Backup rings are useful for many different reasons but the main reason is by blocking or reducing the extrusion gap. This prevents the O-Ring inside to be damaged or extruded causing...

Written By:

Get the latest updates on products, new knowledge base posts, and everything APG!

About The Author

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

Leave a Reply

Your email address will not be published. Required fields are marked*