-

-

November

2021

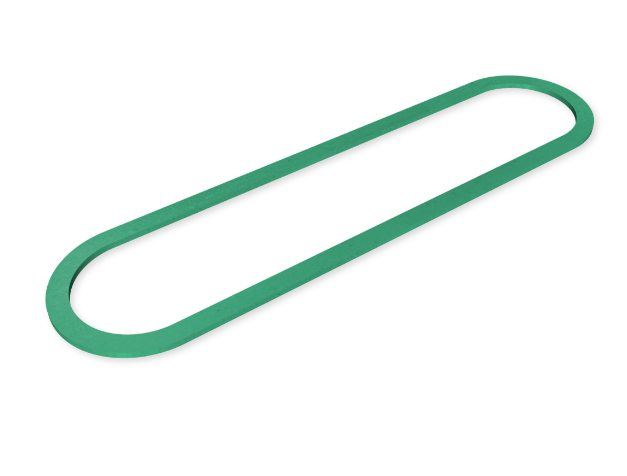

Getting To Know O-Ring Materials: Fluorosilicone

- fluorosilicone

- fluorosilicone o-ring

- aviation

- o-ring

- sealing

Trade Names: LS (DOW), FSE (GE)

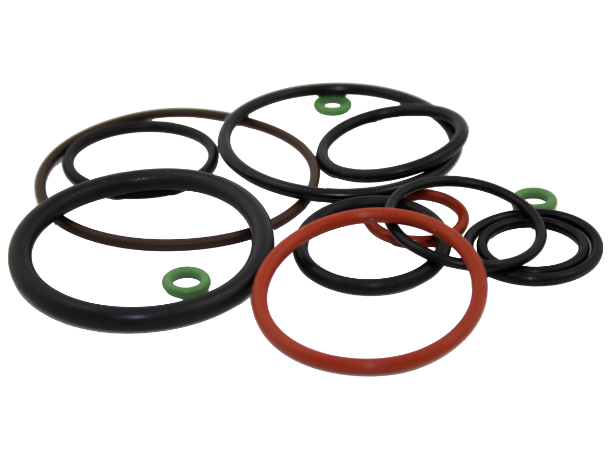

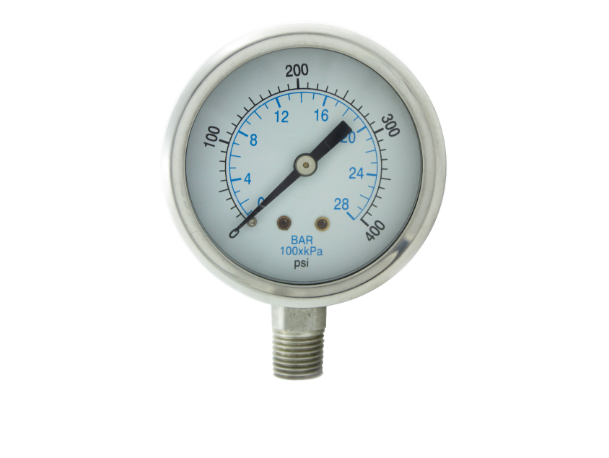

Fluorosilicone, FVMQ is a compound that contains trifluoropropyl, methyl, vinyl, and a combination of silicone which gives it super abilities. Fluorosilicone has an excellent compression set and is stable in extreme temperatures like silicone. Unlike silicone, it offers improved fuel and mineral oil resistance with good electrical properties. There is a wide range of applications FVMQ is used in, such as fuel jet systems, automotive fuel emission systems, petroleum and oil applications, as well as broad temperature range environments. However, because of its insufficient strength and abrasion resistance, its generally recommended to be used only with static applications.

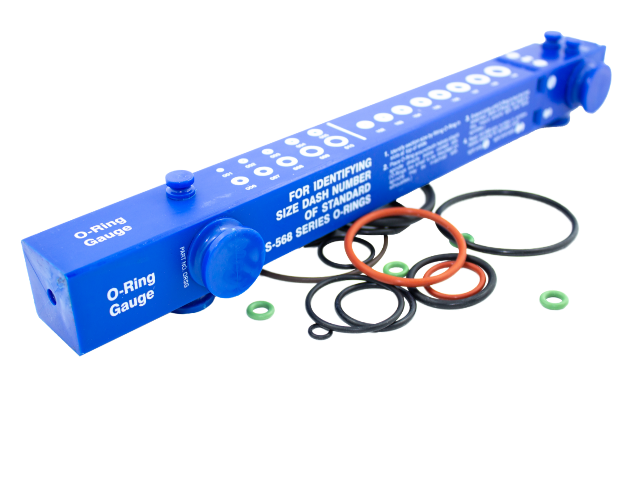

The standard temperature range of Fluorosilicone is between -80ºF (-62ºC) and +400ºF (204ºC) but in dry heat can be serviceable up to 450ºF (232ºC). APG stocks 70 durometer Fluorosilicone o-rings in various sizes. If you need something softer or harder, please contact us. When stored properly, Fluorosilicone can last an infinite amount of years without degradation of the compound. This material is color-coded to be blue however if needed, these rubber rings can be custom ordered to be any color you may like.

Extreme Temperature Performance

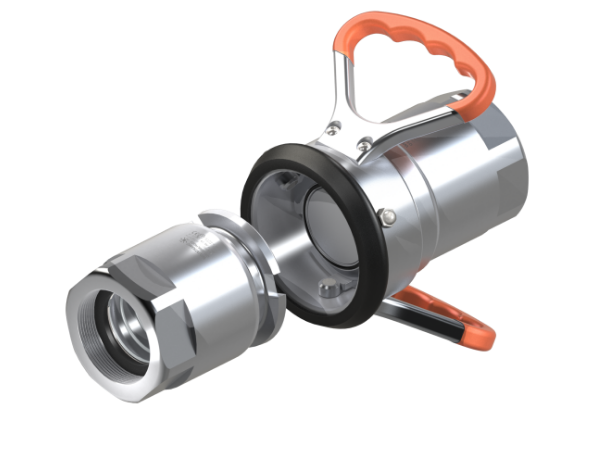

Fluorosilicone has a primary use of inside fuel systems in aerospace applications. This requires an outstanding temperature range as well as resistance to many other elements. FVMQ is resistant to sunlight, ozone, and weathering making it the perfect aviation compound.

Resilience

FVMQ is highly resistant to various factors and can be used in a wide range of industries because of that. This rubber material is resistant to various solvents, oils, temperatures, and compression sets. These characteristics make Fluorosilicone rubber a must for the aviation industry.

Fluorosilicone is available in a variety of sizes to fit your needs. Shop now or contact an expert for help!

Abrasion

FVMQ rubber and o-rings are not meant for dynamic applications. This material does not do well in environments that need abrasive properties in their materials. Fluorosilicone is generally used for static sealing applications due to its inability to resist.

If you are looking for tear-resistant O-Rings, Nitrile based O-Rings might be the material for you!

For Proper O-Ring Material Usage,

Contact the Experts at APG

What is Durometer?

The durometer is a measurement of the hardness of a piece of rubber. However, there are a few different scales the industry uses to measure the durometer of an object. The most popular way is the Shore A durometer scale. Shore A is the way APG measures....

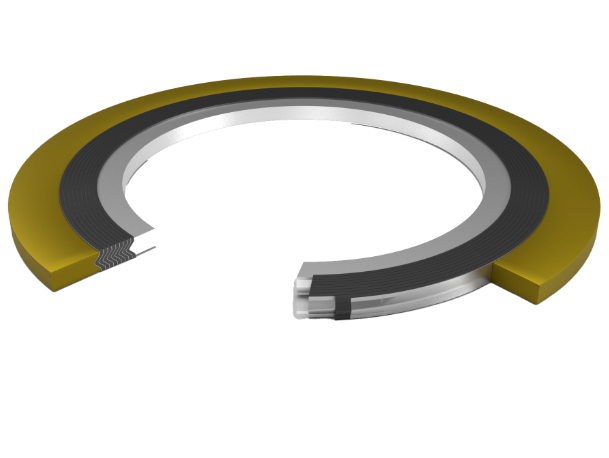

The O-Ring Vulcanization Process

Here at APG, we have a dedicated team with decades of O-ring knowledge and experience readily available to vulcanize any custom O-Ring when you need it most. The vulcanization process consists of using cord material, adhesive, heat, and pressure to combine the two ends together...

Written By:

Stay Connected!

Get the latest updates on products, new knowledge base posts, and everything APG!